More and more precise equipment is required to inspect products and ensure consumer and brand protection. Varpe has therefore developed X-ray inspection and checkweighing equipment specifically for this sector, which can be adapted according to format and customer requirements.

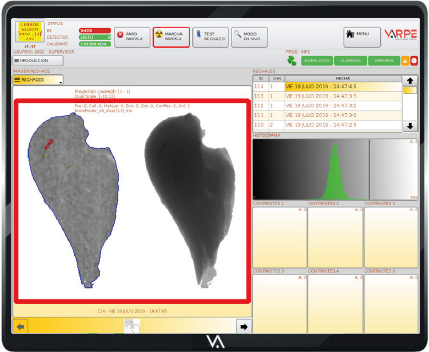

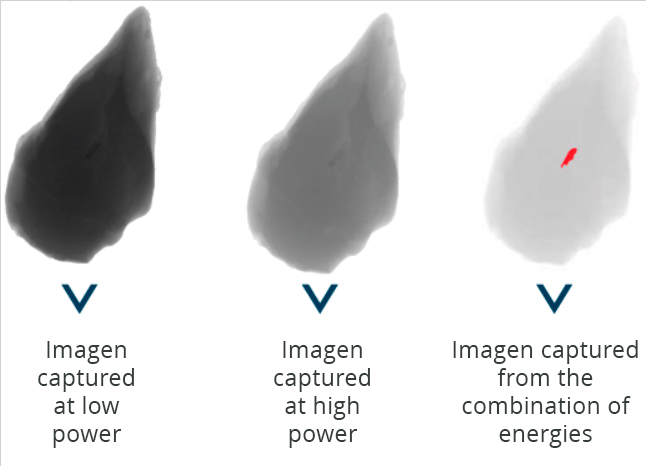

X-ray equipment allows for automatic product inspection and makes it possible to locate contaminants that might otherwise go undetected. They even have special algorithms and functions to increase the sensitivity of the detection when necessary, as in the case of bone localisation.

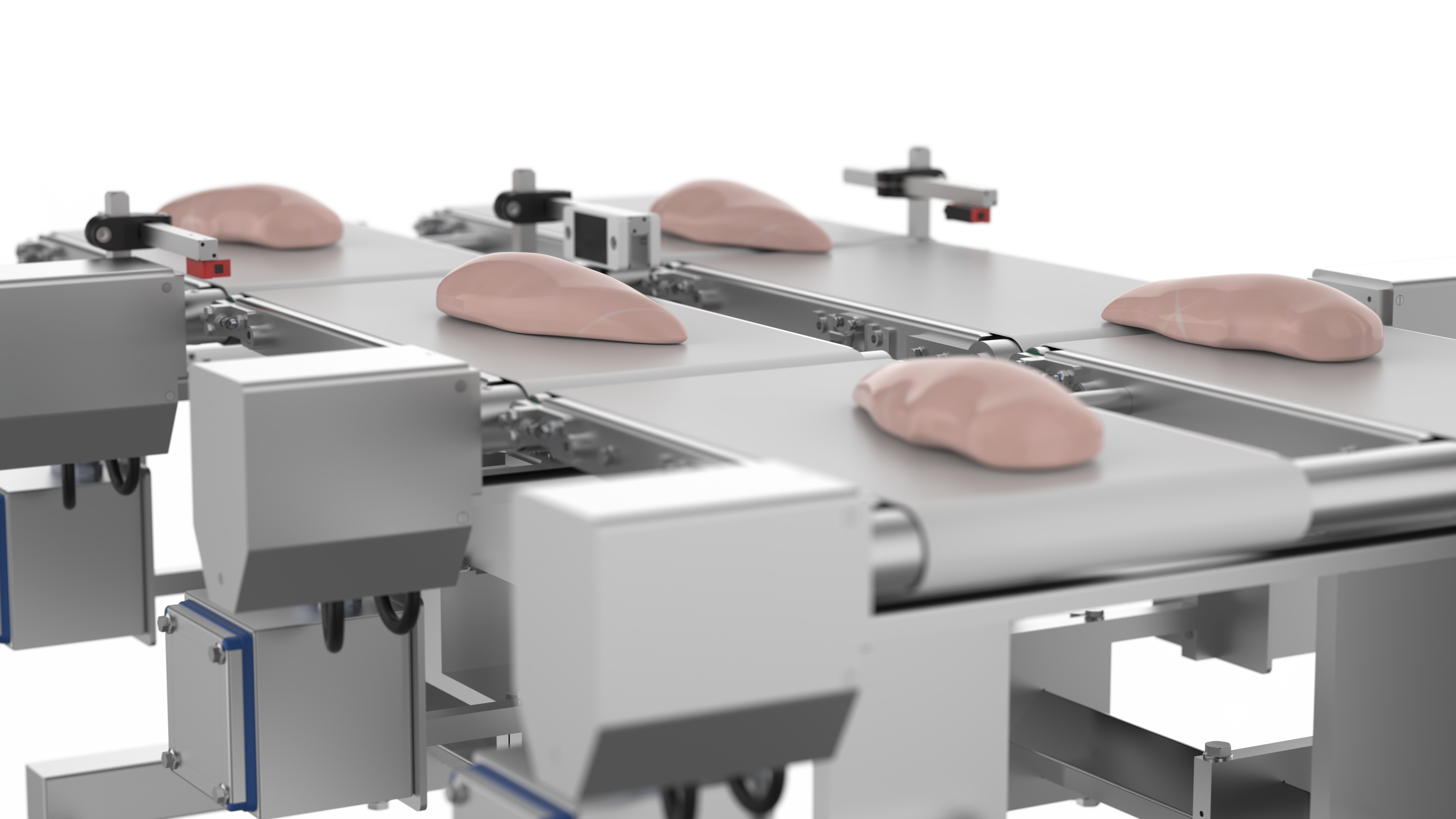

Varpe also has specific checkweighers for weighing products such as chicken breasts or unpackaged hamburgers.

X-ray equipment allows for automatic product inspection and makes it possible to locate contaminants that might otherwise go undetected. They even have special algorithms and functions to increase the sensitivity of the detection when necessary, as in the case of bone localisation.

Varpe also has specific checkweighers for weighing products such as chicken breasts or unpackaged hamburgers.