It is important, both for brand image and consumer law, to ensure that products marketed in different packaging do not differ from one another. This requires uniformity of the product not only in terms of format, but also in terms of quantity. For example, if a consumer buys a product whose packaging is marked 250 g, it is essential that the scale on which the product has been weighed works according to standards to ensure that the quantity the customer is paying for is actually the quantity he is getting.

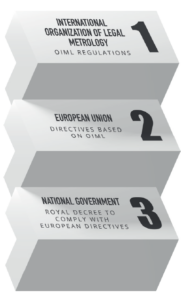

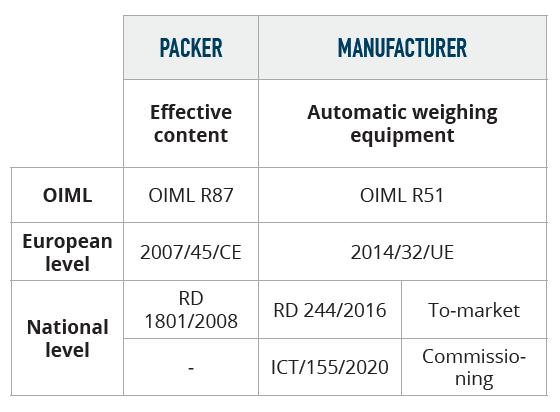

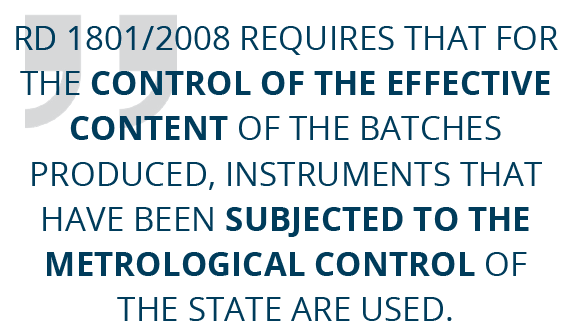

In order to guarantee greater market transparency, a series of rules, directives and decrees are proposed to guarantee greater production rationality.

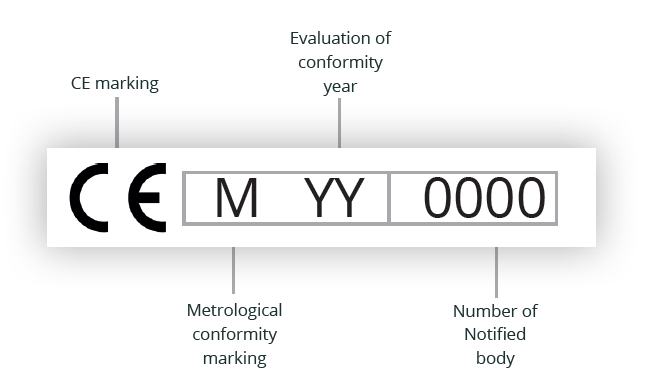

From here it is essential to talk about metrology, the science that studies measurements and guarantees their standardisation through traceability. It operates in scientific, industrial and legal fields and regulates means, methods and instruments, such as dynamic checkweighers.

In order to guarantee greater market transparency, a series of rules, directives and decrees are proposed to guarantee greater production rationality.

From here it is essential to talk about metrology, the science that studies measurements and guarantees their standardisation through traceability. It operates in scientific, industrial and legal fields and regulates means, methods and instruments, such as dynamic checkweighers.