Quality control of beverages is a cornerstone in the food industry, ensuring that products not only comply with current regulations but also meet consumer expectations. The implementation of advanced technologies in this field is crucial to maintain competitiveness and ensure food safety. A leading solution in this area is Varpe's V2000 Rotary checkweigher, specifically designed to meet the demands of markets with particular weighing and quality requirements, such as the alcoholic beverage industry.

HOW TO CARRY OUT QUALITY CONTROL OF BEVERAGES

by marketing on 27 de March de 2024

HOW TO CARRY OUT QUALITY CONTROL OF BEVERAGES

IMPORTANCE OF QUALITY CONTROL IN THE BEVERAGE INDUSTRY

The quality control of beverages, and more specifically the quality control of alcoholic beverages, is fundamental to ensure the integrity of the final product. This process ranges from raw material selection to packaging, with weighing being one of the critical aspects to ensure proper dosage and product uniformity.

In the complex and competitive beverage industry, quality control is not just a requirement, but a fundamental pillar that ensures the success and sustainability of any brand. This meticulous process plays a crucial role at every stage of production, from the careful selection of raw materials to the final packaging processes. This is where quality control of beverages, especially alcoholic beverages, becomes an indispensable task to maintain integrity and confidence in the final product.

RAW MATERIALS SELECTION

The first step in ensuring the quality of any beverage begins with the selection of raw materials. Fruits, grains, water and any other ingredients used must meet specific quality standards to ensure not only the safety but also the desired flavour profile of the final product. In the case of alcoholic beverages, this is especially critical, as the quality of the base alcohol, ferments and flavour ingredients determine the character and market acceptance of the product.

PRODUCTION PROCESSES

Once the raw materials have been selected, the production process must be carefully monitored. Fermentation temperatures, maturation times, and filtering methods, each step influences the final quality of the product. Standardisation of these processes is vital to ensure product consistency. In the production of alcoholic beverages, for example, small variations in the process can have a major impact on taste and overall quality, which in turn can affect consumer perception and brand loyalty.

QUALITY CONTROL DURING PACKAGING

Packaging is another critical stage in the production chain where quality control is essential. Here, weighing becomes a determining factor. Correct dosing ensures that the consumer receives the exact amount of product promised, which is a key component of product integrity. In addition, proper packaging protects the product from contamination and ensures its preservation until it reaches the final consumer. In the context of alcoholic beverages, packaging must also comply with specific regulations that may vary by market, including labelling with nutritional information, health warnings, and alcohol content.

THE ROLE OF WEIGHING IN QUALITY CONTROL

Weighing emerges as one of the most critical aspects of quality control, serving as a key control point to ensure proper dosing and product uniformity in each batch. An accurate weighing system, such as that offered by Varpe's V2000 Rotary checkweigher, is critical to maintaining product consistency and meeting consumer expectations. The ability to take accurate measurements quickly allows for efficient production without compromising quality, ensuring that each bottle, can or pack leaves the production line with the exact amount of product.

WHAT MAKES THE V2000 ROTARY UNIQUE?

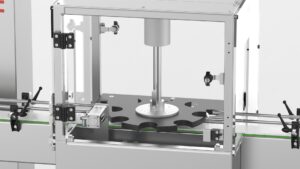

The V2000 Rotary is an innovative solution thanks to its rotary star design, which enables accurate and efficient checkweighing, essential for beverage quality control. Its robust and compact structure fits into limited spaces, while offering advanced weighing technology with maximum accuracy. Equipped with a touch screen and a wide range of communication systems, this checkweigher is perfectly aligned with the needs of modern industry.

VERSATILITY AND HYGIENIC APPROACH

Versatility is another strength of the V2000 Rotary, whose modular system allows for simple and quick installation and commissioning. This is particularly relevant for the quality control of alcoholic beverages, where flexibility in the production line can translate into increased efficiency and productivity. In addition, the hygienic approach in its design ensures that the equipment meets the highest standards of cleanliness and accessibility, crucial in the beverage industry.

BENEFITS OF IMPLEMENTING THE V2000 ROTARY IN QUALITY CONTROL

Adopting the V2000 Rotary in the beverage quality control process provides multiple benefits, from optimising production to ensuring the quality of the final product. Its weighing accuracy prevents errors that could affect brand reputation and consumer satisfaction. In addition, the ability to adapt to different types of containers and liquids makes it an indispensable tool in the beverage industry.

REGULATORY COMPLIANCE AND CONSUMER SATISFACTION

Quality control of alcoholic beverages involves complying with strict health and safety regulations. The V2000 Rotary, by providing accurate and reliable weighing, plays a crucial role in this respect, helping companies to avoid penalties and, most importantly, to protect the health of consumers. This level of commitment to quality not only complies with regulations but also raises the perception of value among consumers, strengthening brand image.

In an increasingly demanding and regulated market, beverage quality control, and in particular the quality control of alcoholic beverages, demands innovative and efficient solutions. Varpe's V2000 Rotary checkweigher is positioned as a key tool in this process, standing out for its accuracy, versatility and hygienic approach. Implementing this technology not only optimises production but also ensures that the final product meets the highest quality standards, satisfying industry needs and consumer expectations.