X-rays are electromagnetic radiation used to inspect the inside of opaque bodies such as foodstuffs, chemicals, pharmaceuticals or any other type of product for contaminants. An X-ray generator emits the energy necessary to compose an image of the inspected product. The product moves linearly on a conveyor belt until it is passed through by the X-ray beam. The resulting energy values are fed to the detector and processed by software, which generates an image from which conclusions are drawn about the product.

X-RAY INSPECTION: BEYOND CONTAMINANTS

by marketing on 9 de August de 2023

How do X-rays work?

Beyond inspection for contaminants

Traditionally, x-ray inspection equipment has been used to detect contaminants in everything from foodstuffs to pharmaceuticals. However, the technology has evolved and is now capable of detecting much more. Some of the new uses of x-rays help in the detection of unusual shapes, missing or excess product, breakage or defects. The following are some of the possible applications on demand and depending on the product:

1.Detection of unusual shapes

Detection of unusual shapes: deformed packages, packages that are too short, too long, or whose width does not conform to the established standard.

Detection of unusual shapes: deformed packages, packages that are too short, too long, or whose width does not conform to the established standard.

2. Detection of included samples

Detection of samples included in the package. In addition to being able to detect if there are any items that should not be there, X-rays can also locate items that should be included, such as samples of another product inside a package.

Detection of samples included in the package. In addition to being able to detect if there are any items that should not be there, X-rays can also locate items that should be included, such as samples of another product inside a package.

3.Measurement of product quantity

Measurement of the amount of product mass. X-ray inspection images can be used to calculate whether a container has the right amount of product in it.

X-ray inspection images can be used to calculate whether a container has the right amount of product inside. Mass tolerances are set for sorting. If the mass is lower than the lowest tolerance, the product is rejected; if the mass is higher than the maximum set by the manufacturer, it will also be rejected for reprocessing.

5. Product level

Product level measurement. It is also possible to analyse whether a product is filled to the right level. Overfills and underfills pose a threat to production costs and customer satisfaction.

7. Vacuum and seals

Vacuum and seal maintenance. It is equally important to check that, if a product is vacuum packed, it remains in perfect condition. Similarly, x-ray inspection can check whether a product's seal remains airtight.

Measurement of the amount of product mass. X-ray inspection images can be used to calculate whether a container has the right amount of product in it.

X-ray inspection images can be used to calculate whether a container has the right amount of product inside. Mass tolerances are set for sorting. If the mass is lower than the lowest tolerance, the product is rejected; if the mass is higher than the maximum set by the manufacturer, it will also be rejected for reprocessing.

5. Product level

Product level measurement. It is also possible to analyse whether a product is filled to the right level. Overfills and underfills pose a threat to production costs and customer satisfaction.

7. Vacuum and seals

Vacuum and seal maintenance. It is equally important to check that, if a product is vacuum packed, it remains in perfect condition. Similarly, x-ray inspection can check whether a product's seal remains airtight.

4. Measurement of compartments

Compartmentalised mass measurement. In the case of multi-compartment products, X-ray inspection allows to detect whether the product is in the right place.

6. Watertightness

Tightness. Measuring the space between the head of a bottle and the cap is important to check the perfect seal of the product and to maintain its freshness.

8. Breaks and missing parts

Identification of broken or missing parts. X-rays can be used to check whether a product is intact or broken, or even to detect missing components. is intact or broken and even detect if any of its components are missing. This technical note looks in more detail at the latter case, applied especially to pharmaceutical blister packs. pharmaceutical products.

Compartmentalised mass measurement. In the case of multi-compartment products, X-ray inspection allows to detect whether the product is in the right place.

6. Watertightness

Tightness. Measuring the space between the head of a bottle and the cap is important to check the perfect seal of the product and to maintain its freshness.

8. Breaks and missing parts

Identification of broken or missing parts. X-rays can be used to check whether a product is intact or broken, or even to detect missing components. is intact or broken and even detect if any of its components are missing. This technical note looks in more detail at the latter case, applied especially to pharmaceutical blister packs. pharmaceutical products.

X-ray inspection for blister quality control

Two X-ray applications are available to ensure product integrity:

1. Missing element count.

2. Breakage detection.

This can be applied to a multitude of formats, but in this case study we will apply these technologies to blister detection in the pharmaceutical sector. The objective of the first application is to ensure that the blister is complete and therefore no pills are missing. This can be done thanks to an algorithm that consists of a unit check in blister packs containing several pills. The algorithm is pre-prepared to detect a missing pill in blister packs similar to the one in the picture.

For a correct inspection, one of Varpe's IRIX systems and a good adjustment of the algorithm in question should be available. As can be seen in the following figure, the equipment counts all the pills and when it checks that the blister is complete, it validates the product. On the other hand, when it detects that one of the pills is missing, it rejects the product.

1. Missing element count.

2. Breakage detection.

This can be applied to a multitude of formats, but in this case study we will apply these technologies to blister detection in the pharmaceutical sector. The objective of the first application is to ensure that the blister is complete and therefore no pills are missing. This can be done thanks to an algorithm that consists of a unit check in blister packs containing several pills. The algorithm is pre-prepared to detect a missing pill in blister packs similar to the one in the picture.

For a correct inspection, one of Varpe's IRIX systems and a good adjustment of the algorithm in question should be available. As can be seen in the following figure, the equipment counts all the pills and when it checks that the blister is complete, it validates the product. On the other hand, when it detects that one of the pills is missing, it rejects the product.

On the other hand, if in addition to the absence of a pill, a breakage in the blister pack is to be detected, a high-definition imaging system can be used, which allows much more detailed product captures of the blister pack itself, as shown below.

With this technology, the system can not only count the items, but it can also check that there are no tears in any of the blister compartments; in the image below, it shows the imperfection in any of the blister compartments below, it signals an imperfection in one of the parts and the product is immediately rejected. In this way, the quality of the product and the image of the brand are protected. Thanks to these HD images, the equipment would also be able to detect if the tablets inside the blister pack are broken or cracked, as can be seen in the example below.

With this technology, the system can not only count the items, but it can also check that there are no tears in any of the blister compartments; in the image below, it shows the imperfection in any of the blister compartments below, it signals an imperfection in one of the parts and the product is immediately rejected. In this way, the quality of the product and the image of the brand are protected. Thanks to these HD images, the equipment would also be able to detect if the tablets inside the blister pack are broken or cracked, as can be seen in the example below.

Deep learning and X-ray inspection

Given the enormous possibilities offered by X-ray inspection, new artificial intelligence technologies are being introduced to

artificial intelligence technologies are being incorporated to enable even greater accuracy in the detection of defective products. One of these is deep learning.

The aim of deep learning is to make detectable what is visible to the human eye by creating a neural network trained for a specific detection.

For example, if we train the model with an image gallery of pears and an image gallery of apples together with an algorithm on an X-ray inspection machine, it will be able to recognise the usual characteristics of each and distinguish whether what it is inspecting is a pear or an apple.

artificial intelligence technologies are being incorporated to enable even greater accuracy in the detection of defective products. One of these is deep learning.

The aim of deep learning is to make detectable what is visible to the human eye by creating a neural network trained for a specific detection.

For example, if we train the model with an image gallery of pears and an image gallery of apples together with an algorithm on an X-ray inspection machine, it will be able to recognise the usual characteristics of each and distinguish whether what it is inspecting is a pear or an apple.

How is deep learning implemented?

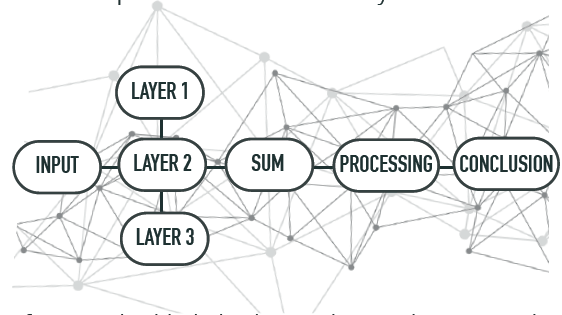

The most common technique is to simulate a neural network within the data analysis software. This network is made up of different layers; each of these layers is a specialist in a characteristic of the product being inspected (e.g. shape, colour, size, etc.). The information obtained by these layers is aggregated, processed and provides a result based on the patterns and examples that have been initially entered.

If we apply this operation to the previous example, it would work by evaluating the image inputs and analysing all the layers to sum them up and process them in order to draw a conclusion: whether what you have just seen is an apple or not.

If we apply this operation to the previous example, it would work by evaluating the image inputs and analysing all the layers to sum them up and process them in order to draw a conclusion: whether what you have just seen is an apple or not.

Deep learning aplications

Varpe is developing several applications based on deep learning for X-ray inspection with different casuistry and product typologies. The first of these is object detection.

This typology has several uses:

- With this first algorithm, the team is able to identify and distinguish between various products and classify them effectively to avoid the costs and time of human labour that would be involved in making this distinction manually, as in the example of pears and apples.

• Object detection can also be useful to control the number of units in a product, as seen in the case of blister packs where the number of tablets was counted.

• This algorithm also makes it possible to locate the product to check, for example, whether or not it is inside its packaging.

- The second deep learning application that has been developed is called anomaly detection and is very useful for ensuring product integrity. It allows us to find defects in the object we are analysing, such as breaks, dents or deformations. We have also seen an example with the detection of perforated blister packs.

This typology has several uses:

- With this first algorithm, the team is able to identify and distinguish between various products and classify them effectively to avoid the costs and time of human labour that would be involved in making this distinction manually, as in the example of pears and apples.

• Object detection can also be useful to control the number of units in a product, as seen in the case of blister packs where the number of tablets was counted.

• This algorithm also makes it possible to locate the product to check, for example, whether or not it is inside its packaging.

- The second deep learning application that has been developed is called anomaly detection and is very useful for ensuring product integrity. It allows us to find defects in the object we are analysing, such as breaks, dents or deformations. We have also seen an example with the detection of perforated blister packs.

- The third development carried out with deep learning consists of intelligent segmentation. This type of segmentation makes it possible to distinguish the different parts or areas of the product that a human can see but a machine cannot. For example, in a bottle, it would be able to differentiate the cap from the body and thus analyse the part that is of most interest to the manufacturer. It could be used to measure the body of the bottle,

size, or even check for foreign objects in the cap of the product.

The future of products inspection

There are endless possibilities for development in X-ray inspection in the not too distant future, especially if we take into account deep learning, which allows us to go much further than what has traditionally been done with the detection of contaminants. This technology will push quality control to the next level in the coming years, and will make inspection much more efficient and accurate, not only in locating foreign bodies but also in a multitude of applications of all kinds, making detectable what was previously only visible to the human eye.