X-ray inspection systems are increasingly being used in the quality control of food, chemical and pharmaceutical products in order to ensure that the final product reaching the consumer is completely safe and free of foreign bodies. Many manufacturers are incorporating this type of equipment into their production lines, but what should be taken into account when choosing the right machinery?

First of all, we should clarify what x-rays are. X-rays are electromagnetic radiation of the same nature as radio waves, microwave waves or infrared rays. Thanks to their particularities, these types of rays are very useful for inspecting opaque bodies such as foodstuffs, detergent bottles or any kind of product for foreign bodies.

But how does an x-ray inspection system work?

Broadly speaking, an X-ray generator emits the required energy and the product moves linearly on a conveyor belt until it is passed through by an X-ray beam. The energy values resulting from this process are fed to the detector, which composes a digital image. This is processed by Varpe's software, which accurately detects any foreign bodies that may be inside the product. If a foreign body is detected, the equipment automatically rejects it.

Before making the choice of equipment, several general questions must be asked: can the equipment be easily adapted to the line? how many products will we be working with? are they very different formats? can the production be fully controlled?

In addition to all these questions, several points intrinsic to the equipment and production must be analysed:

1. SUPPLIER: Look for experienced suppliers.

2. PRODUCT TYPE: Consider the type of product we wish to analyse.

3. FOREIGN BODIES: Consider the type and size of the foreign body to be searched for.

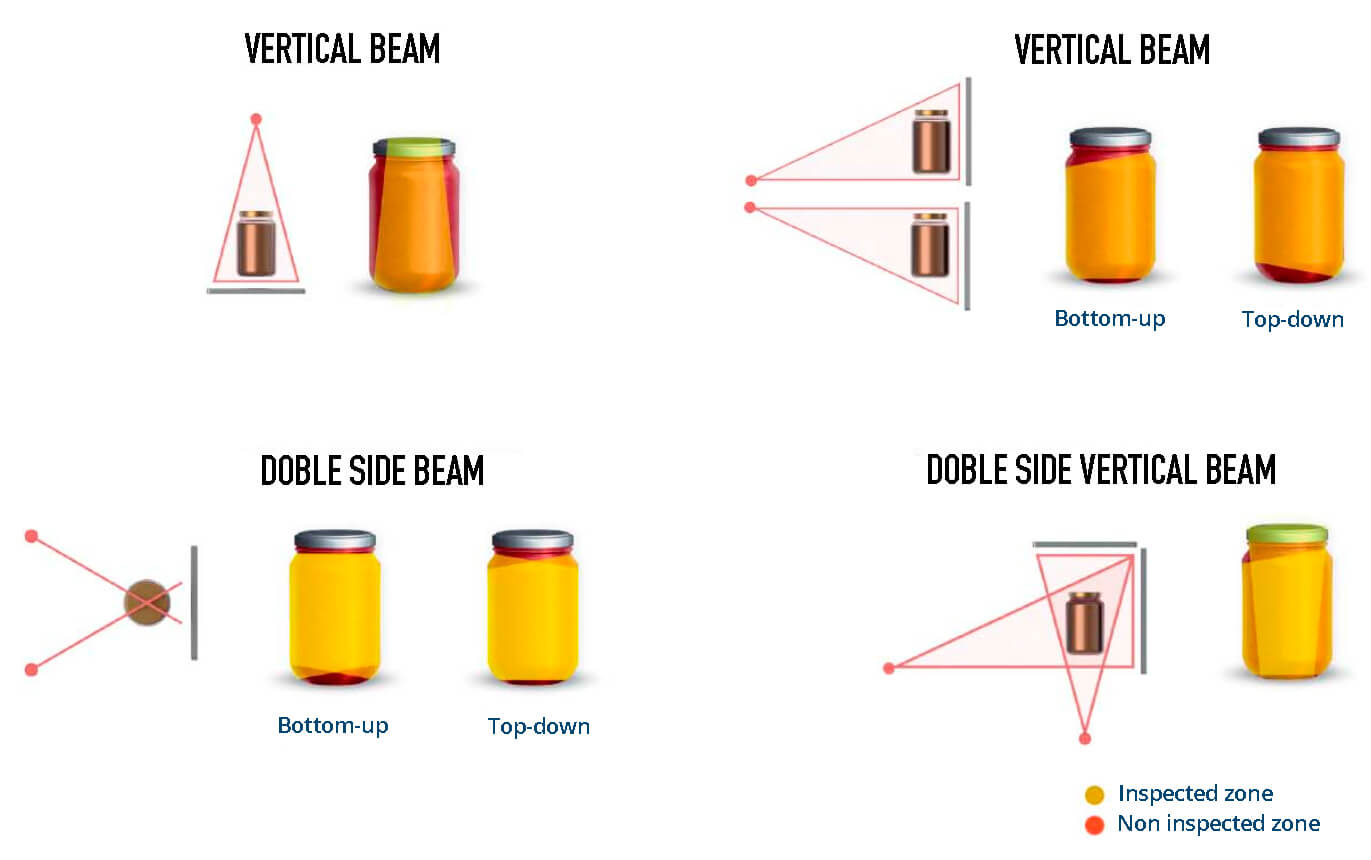

4. BEAM GEOMETRY: Consider the geometry of the X-ray beam and the characteristics of the image.

5. SPEED: Consider the speed of passage and inspection of the product.

6. PERFORMANCE: Consider the performance of the equipment.

7. ELECTRICAL POWER: Take into account the power of the equipment that we are going to need.

First of all, we should clarify what x-rays are. X-rays are electromagnetic radiation of the same nature as radio waves, microwave waves or infrared rays. Thanks to their particularities, these types of rays are very useful for inspecting opaque bodies such as foodstuffs, detergent bottles or any kind of product for foreign bodies.

But how does an x-ray inspection system work?

Broadly speaking, an X-ray generator emits the required energy and the product moves linearly on a conveyor belt until it is passed through by an X-ray beam. The energy values resulting from this process are fed to the detector, which composes a digital image. This is processed by Varpe's software, which accurately detects any foreign bodies that may be inside the product. If a foreign body is detected, the equipment automatically rejects it.

Before making the choice of equipment, several general questions must be asked: can the equipment be easily adapted to the line? how many products will we be working with? are they very different formats? can the production be fully controlled?

In addition to all these questions, several points intrinsic to the equipment and production must be analysed:

1. SUPPLIER: Look for experienced suppliers.

2. PRODUCT TYPE: Consider the type of product we wish to analyse.

3. FOREIGN BODIES: Consider the type and size of the foreign body to be searched for.

4. BEAM GEOMETRY: Consider the geometry of the X-ray beam and the characteristics of the image.

5. SPEED: Consider the speed of passage and inspection of the product.

6. PERFORMANCE: Consider the performance of the equipment.

7. ELECTRICAL POWER: Take into account the power of the equipment that we are going to need.