When we hear about X-rays, the first thing that comes to mind is the hospital, right? But did you know that this technology also plays a crucial role in something as everyday as the food we put in our mouths? Yes, you read that right. X-rays in food are an essential tool to ensure that what we eat is safe and of high quality. So, let's dive into this fascinating world and find out exactly what role x-rays play in our food.

WHAT IS THE PURPOSE OS THE X-RAYS IN FOOD?

by marketing on 7 de March de 2024

WHAT IS THE PURPOSE OS THE X-RAYS IN FOOD?

THE IMPORTANCE OF FOOD SECURITY

X-rays help keep our food safe, it is crucial to understand why food safety is so important. Every year, millions of people suffer from foodborne illnesses that could be prevented with the right control measures. This is where X-ray inspection systems come into play, ensuring that what ends up on our plate is not only delicious, but also safe to eat.

HOW DO X-RAYS WORK IN FOOD?

Food X-rays work in a similar way to medical X-rays, but instead of looking for broken bones, they look for foreign objects or defects in food products. X-ray inspection systems can detect metals, glass, stones, and other dense materials that should not be in food. But that's not all; they are also able to identify quality problems, such as product inconsistency.

THE VERSALITY OF X-RAY

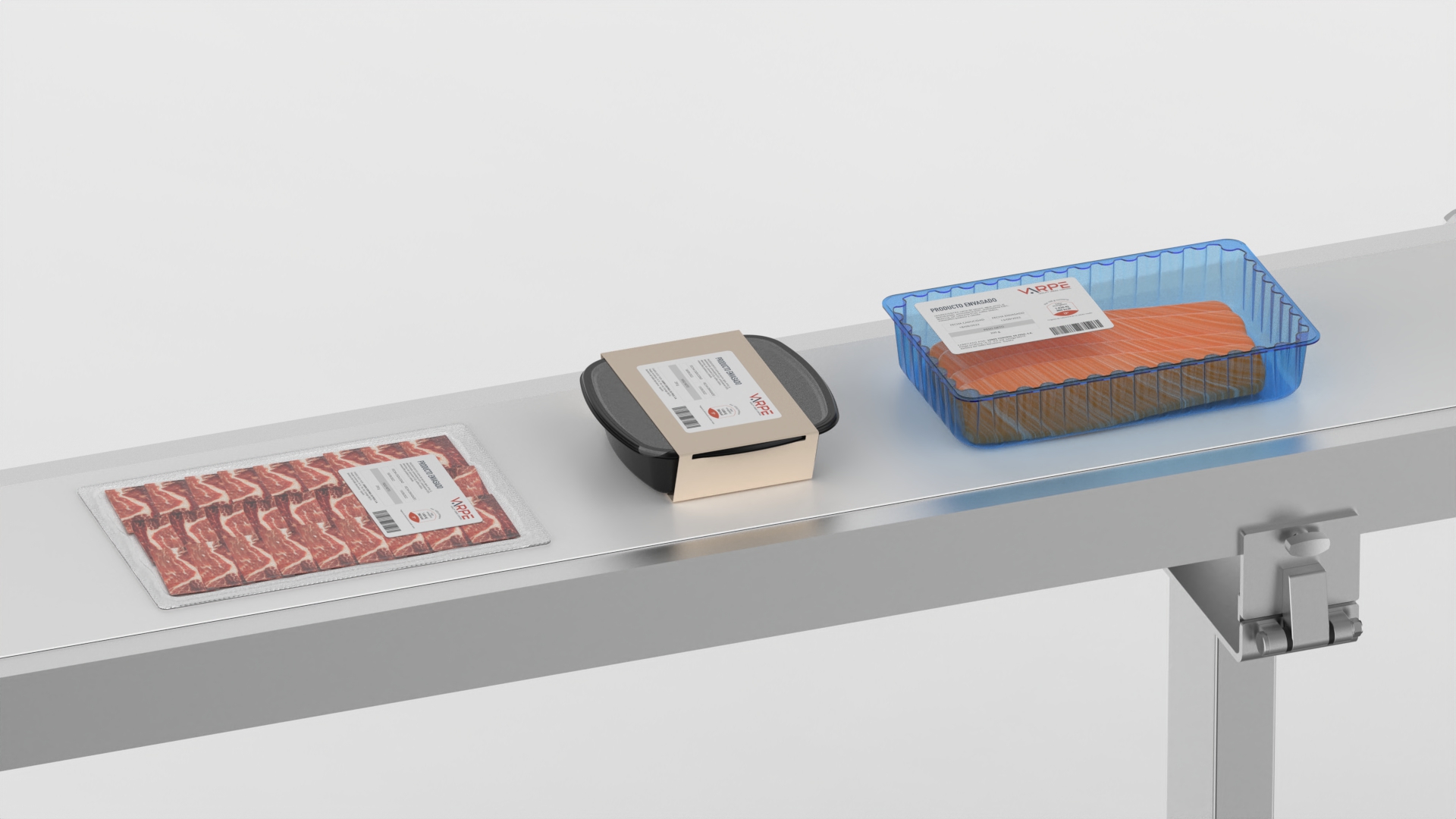

One of the great benefits of x-rays in food is their versatility. They can be used on a wide range of products, from packaged and canned foods to bulk fruit and vegetables. No matter the shape, size or type of packaging; X-rays inspect through them to ensure everything is in order.

BENEFITS OF X-RAY IN FOOD

The use of X-rays in the food industry is not just a technological breakthrough; it is a revolution in how we ensure that the food that reaches our tables is safe, pure and of the highest quality. Let's dig a little deeper into these benefits to understand their real impact.

CONTAMINANT DETECTION

X-ray detection of contaminants in food is undoubtedly one of its most valuable applications. But how exactly does this process work? Inspection systems use x-rays to examine the food product, creating a digital image that shows the presence of foreign material. This technology is so accurate that it can even identify contaminants of very small size, which would otherwise be impossible to detect using visual or manual inspection methods.

The ability to detect a wide range of materials, including metals, glass, stones, and certain types of plastics, is crucial. This not only helps prevent these potentially hazardous materials from reaching the consumer, but also protects food companies from the legal and financial repercussions associated with recalls. Not only are recalls costly, but they can also damage a brand's reputation, having a long-term impact on consumer confidence.

The ability to detect a wide range of materials, including metals, glass, stones, and certain types of plastics, is crucial. This not only helps prevent these potentially hazardous materials from reaching the consumer, but also protects food companies from the legal and financial repercussions associated with recalls. Not only are recalls costly, but they can also damage a brand's reputation, having a long-term impact on consumer confidence.

COMPLIANCE WITH QUALITY STANDARDS

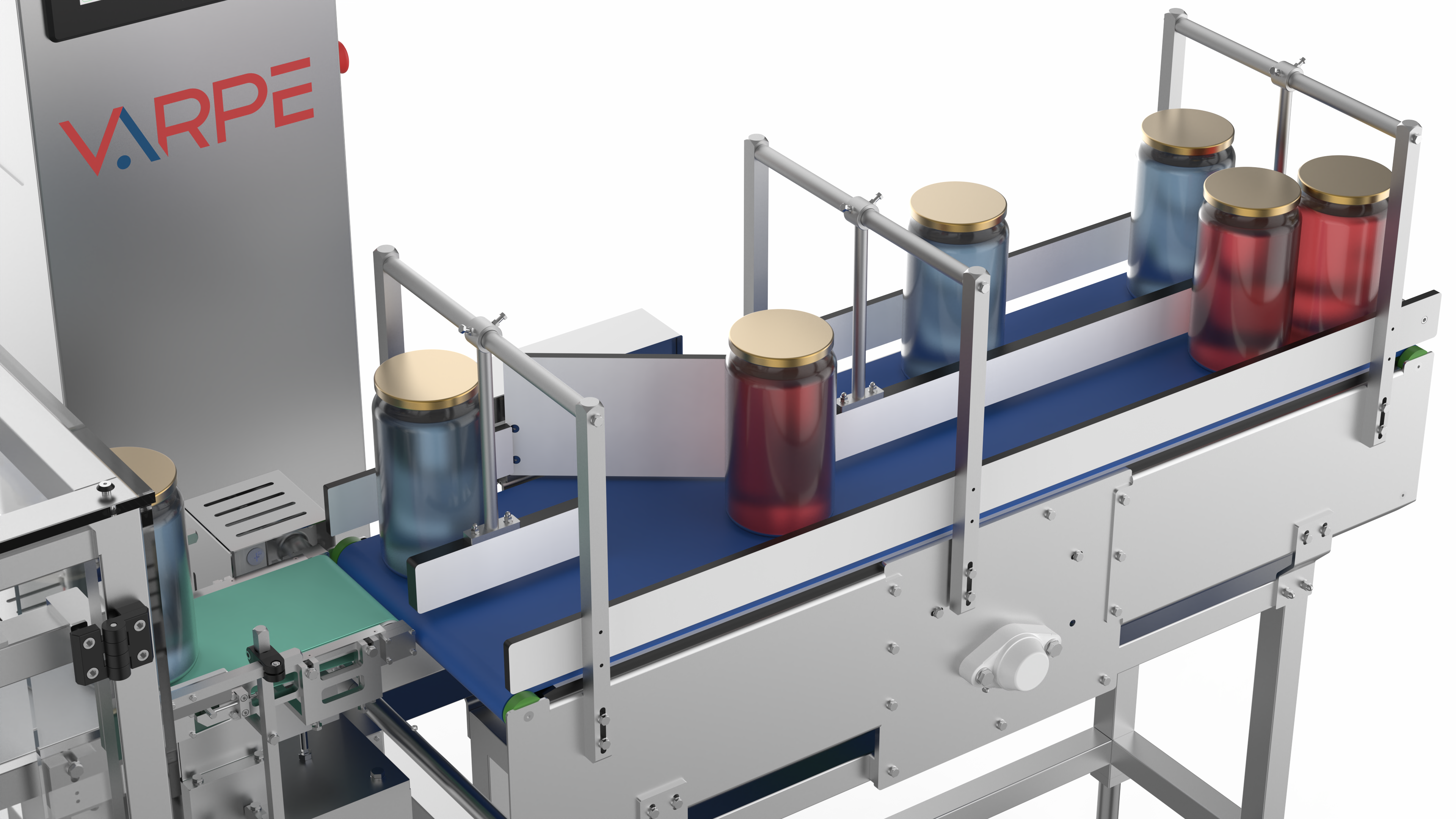

Beyond the detection of unwanted materials, x-ray in food plays a crucial role in meeting quality standards. This technology allows for a non-intrusive and detailed assessment of every product that passes through the production line, ensuring that all aspects, from integrity to packaging, meet the strictest quality standards.

The use of x-rays to verify product integrity includes ensuring that there are no internal fractures in frozen foods or verifying that packaged products are complete and undamaged. In terms of composition, x-ray systems can assess the even distribution of ingredients within a product, which is especially important in processed foods where consistency is key to meeting consumer expectations.

The use of x-rays to verify product integrity includes ensuring that there are no internal fractures in frozen foods or verifying that packaged products are complete and undamaged. In terms of composition, x-ray systems can assess the even distribution of ingredients within a product, which is especially important in processed foods where consistency is key to meeting consumer expectations.

OPTIMISATION OF PRODUCTION

Implementing X-ray inspection systems on the food production line not only improves product safety and quality; it also optimises the production process itself. These systems provide almost instant feedback on product quality and safety, allowing companies to quickly address any problems detected. This significantly reduces waste, as defective products can be removed from the production line before they progress to later stages, saving time and resources.

In addition, the ability to perform fast and accurate inspections improves operational efficiency, allowing food companies to process higher volumes of product without compromising quality. This is not only beneficial from a profitability perspective, but also helps to meet market demand more effectively, ensuring that consumers have consistent access to safe, high quality products.

In addition, the ability to perform fast and accurate inspections improves operational efficiency, allowing food companies to process higher volumes of product without compromising quality. This is not only beneficial from a profitability perspective, but also helps to meet market demand more effectively, ensuring that consumers have consistent access to safe, high quality products.

IMPROVING PRODUCTION EFFICIENCY

X-ray inspection systems are also a valuable tool for improving the efficiency of food production. By quickly identifying quality or contamination issues, they enable companies to correct these problems in a timely manner, reducing waste and improving profitability.

ARE X-RAY IN FOOD SAFE?

Now, you may be wondering whether the use of X-rays in food is safe. The short answer is yes. The levels of radiation used in food inspection are extremely low and do not pose any health risks or alter the quality or taste of food. In fact, the safety and efficacy of these systems are widely endorsed by regulatory agencies around the world.

LOOKING TO THE FUTURE

X-ray technology in the food industry is constantly evolving, looking for more efficient and effective ways to ensure food safety and quality. As technology advances, we can expect even more accurate and faster systems, which will undoubtedly contribute to a safer food chain for all.

In short, X-rays in food are an essential tool in the fight for food safety. Not only do they help detect and prevent contamination, but they also ensure that quality standards remain high. So, the next time you bite into that apple or open that can of preserves, remember the crucial role that x-rays may have played in ensuring that your food is safe and free from unwanted surprises.