The food industry, one of the most critical industries for public health and consumer confidence, constantly faces the challenge of ensuring that products reach the hands of consumers in perfect condition. One of the biggest challenges is the detection of foreign bodies, such as fragments of metal, glass, plastic or other materials, which can contaminate food during the production process or during the raw material procurement stage. In this context, artificial intelligence (AI) has emerged as a revolutionary tool, offering innovative solutions to ensure higher standards of safety, quality and efficiency.

QUALITY CONTROL PLAN: TIPS TO EXCELLENCE

by marketing on 19 de March de 2025

ARTIFICIAL INTELLIGENCE IN FOREIGN BODY DETECTION IN THE FOOD INDUSTRY

THE CHALLENGE OF DETECTING THE UNDETECTABLE

The presence of foreign bodies in food not only poses a health risk, but can also lead to lose of confidence in a brand, costly product recalls and regulatory sanctions. Over the years, the industry has implemented technologies such as x-ray, metal detectors and machine vision systems. While these technologies have been effective, they sometimes lack the accuracy and adaptability to address the most complex scenarios, such as the detection of non-metallic materials or in products with sparse and varied compositions.

This is where AI makes a difference. By combining advanced machine learning algorithms with image and data processing techniques, modern systems can identify patterns, learn from errors and continuously improve their performance. This opens up a world of possibilities for foreign body detection with higher accuracy and lower false positive rates.

This is where AI makes a difference. By combining advanced machine learning algorithms with image and data processing techniques, modern systems can identify patterns, learn from errors and continuously improve their performance. This opens up a world of possibilities for foreign body detection with higher accuracy and lower false positive rates.

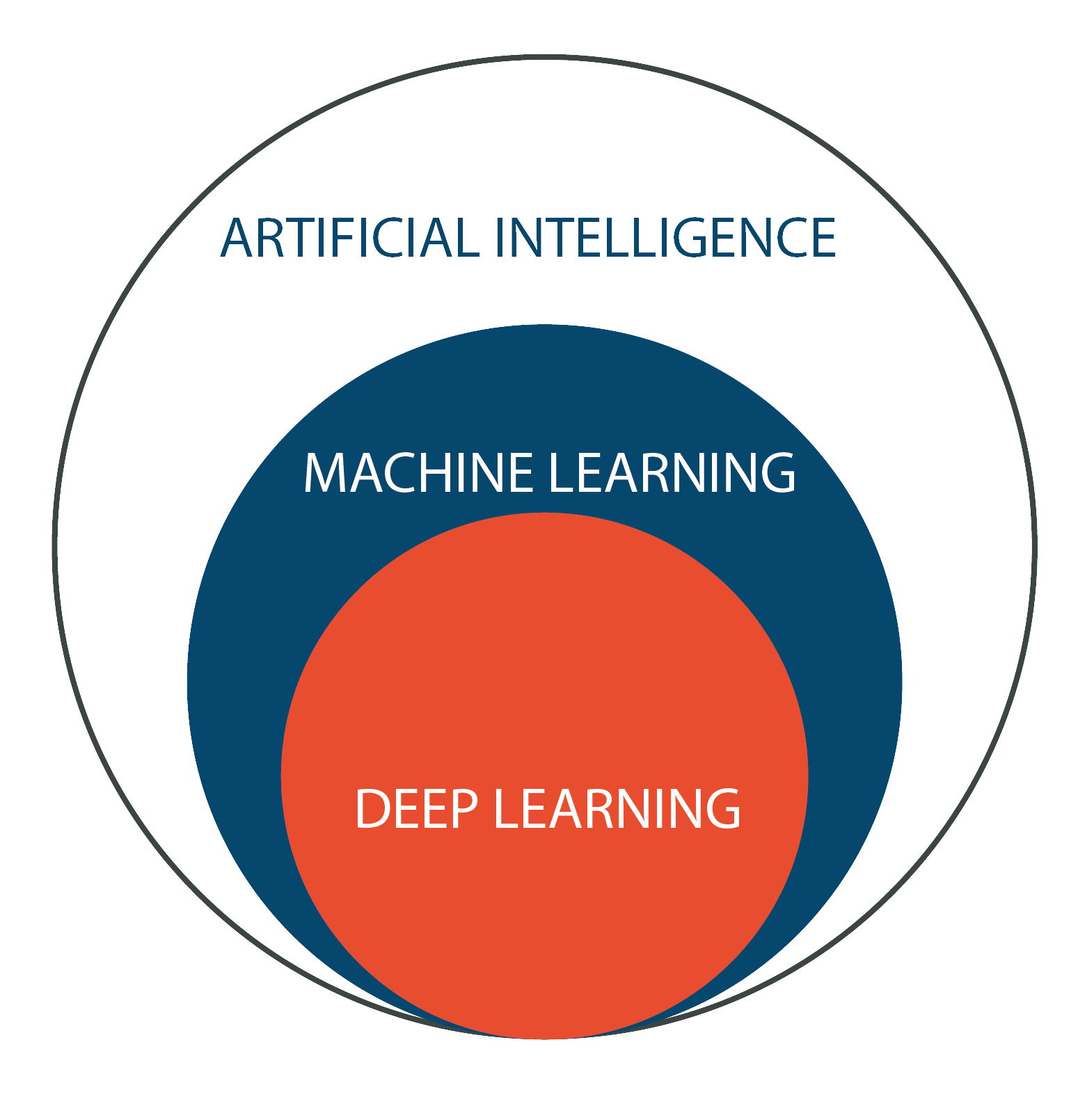

ARTIFICIAL INTELLIGENCE, MACHINE LEARNING AND DEEP LEARNING:

THE TECHNOLOGY TRANSFORMING THE FUTURE

· Artificial intelligence (AI) is much more than technology; it is the engine of innovation that is revolutionising industries. From automating complex tasks to making intelligent decisions, AI is leading the way to a more efficient and connected world.

· On the other hand, deep learning, the most advanced evolution of machine learning, allows machines to process large volumes of data and perform in-depth analysis. It is the key behind many analytics today.

· Within AI, machine learning is the secret for machines to learn and adapt without direct human intervention. Thanks to this ability, we now have assistants that can optimise processes.

HOW DOES THE IA TRANSFORM FOREIGN BODY DETECTION?

X-ray inspection technology has revolutionised inspection processes in industries such as food and pharmaceuticals, providing accurate and efficient solutions to ensure product safety and functionality.

Smart Vision Systems

AI empowers detection systems, allowing them to analyse images with greater certainty. For example, in X-ray systems, AI algorithms can differentiate between safe and hazardous materials, even in high-density products or complex packaging.

Machine Learning for Adaptability

Supervised and unsupervised learning algorithms can be trained to recognise specific foreign bodies in different products. As the systems process more data, they become more accurate, significantly reducing false positives and detection failures.

Predictive Analysis

AI not only detects foreign bodies, but also makes it possible to anticipate critical points in the production process where contamination is most likely to occur. This facilitates the implementation of preventive measures, improving safety from the start of the supply chain.

Reducing Human Errors

With the implementation of AI, reliance on manual inspection, which is often subject to human limitations such as fatigue or misinterpretation, is reduced. This not only increases efficiency, but also ensures constant vigilance.

INSPIRATION FOR A SAFER AND MORE EFFICIENT FUTURE

The integration of AI in food foreign body detection is not just a trend, but a necessity in a world where consumers are demanding safer products and regulations are getting stricter. This technology not only enables companies to meet higher standards, but also gives them a competitive advantage in a globalised market.

Moreover, the impact of AI goes beyond the technology itself. It invites us to rethink production processes, focusing on prevention rather than correction, and to adopt a more collaborative approach between humans and machines. AI-powered sensing systems do not replace human supervision, but complement it, creating an environment where technology and human expertise work hand in hand to ensure products of exceptional quality.

Artificial intelligence is not just a tool to solve current problems; it is an engine of innovation that drives change towards safer, more efficient and sustainable processes.

Moreover, the impact of AI goes beyond the technology itself. It invites us to rethink production processes, focusing on prevention rather than correction, and to adopt a more collaborative approach between humans and machines. AI-powered sensing systems do not replace human supervision, but complement it, creating an environment where technology and human expertise work hand in hand to ensure products of exceptional quality.

Artificial intelligence is not just a tool to solve current problems; it is an engine of innovation that drives change towards safer, more efficient and sustainable processes.

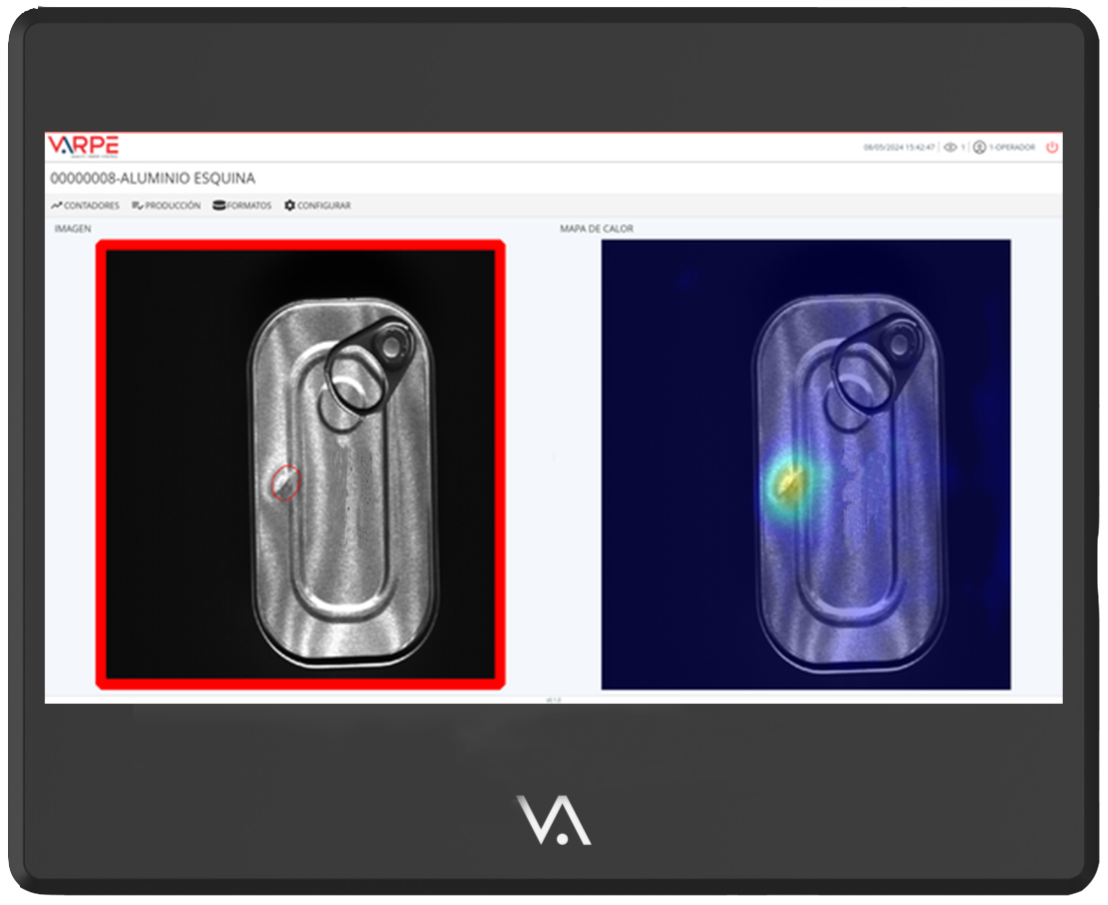

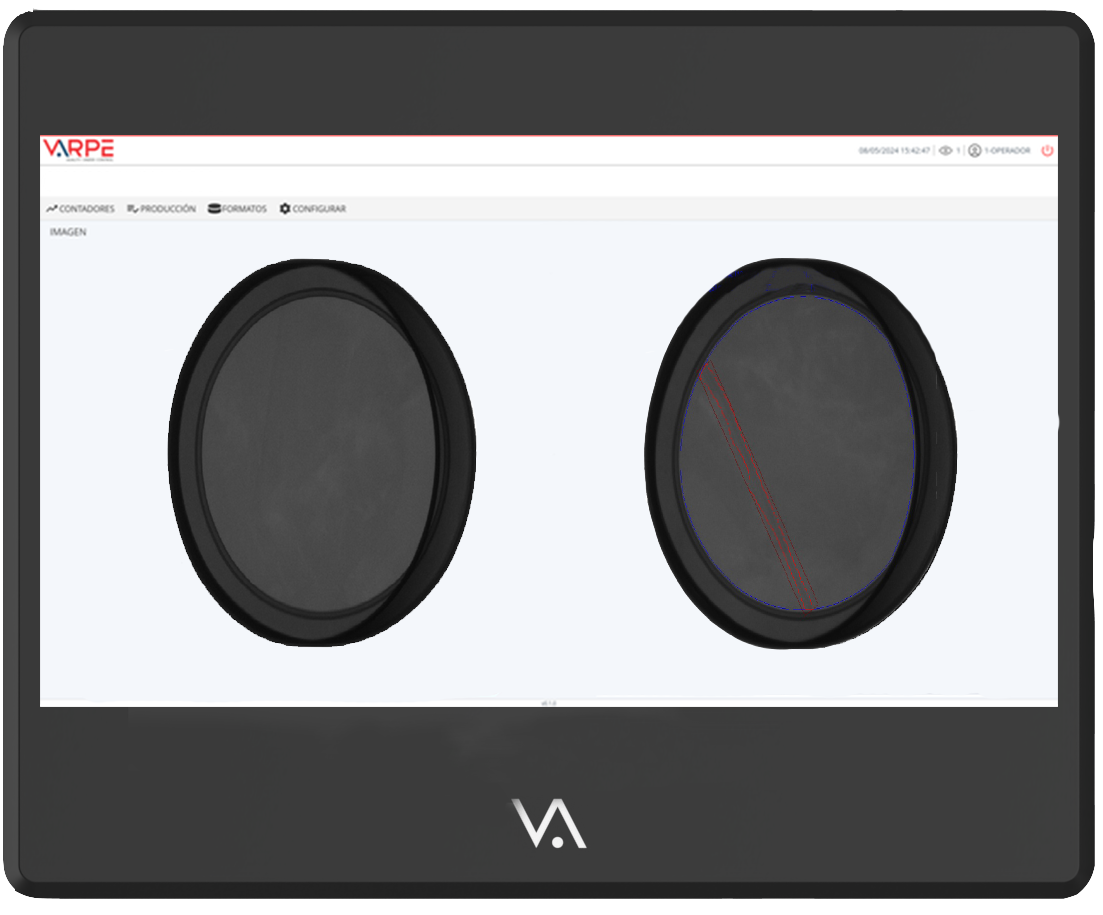

THE IA REVOLUTION IN VARPE QUALITY CONTROL SYSTEMS

At Varpe Weight Control, we are committed to continuous improvement and innovation, integrating cutting-edge technologies into our quality control systems to offer more accurate, efficient solutions tailored to our customers' needs. The incorporation of artificial intelligence (AI) into our products is a key step towards optimising industrial processes and meeting the highest quality standards.

Artificial intelligence (AI) plays a key role in the evolution of our checkweighing systems, x-ray inspection systems and machine vision systems. Through advanced machine learning algorithms, our machines are able to analyse and process large amounts of data in real time, detecting deviations, patterns and errors with high accuracy. This allows automatic adjustments to be made to the production process, resulting in more efficient and sustainable production.

Artificial intelligence (AI) plays a key role in the evolution of our checkweighing systems, x-ray inspection systems and machine vision systems. Through advanced machine learning algorithms, our machines are able to analyse and process large amounts of data in real time, detecting deviations, patterns and errors with high accuracy. This allows automatic adjustments to be made to the production process, resulting in more efficient and sustainable production.

AI enhances predictive maintenance, anticipating potential failures before they occur, minimising downtime and extending equipment life.

In short, the incorporation of artificial intelligence into Varpe's quality control systems represents not only a technological improvement, but also a commitment to excellence, sustainability and competitiveness for our customers.

In short, the incorporation of artificial intelligence into Varpe's quality control systems represents not only a technological improvement, but also a commitment to excellence, sustainability and competitiveness for our customers.