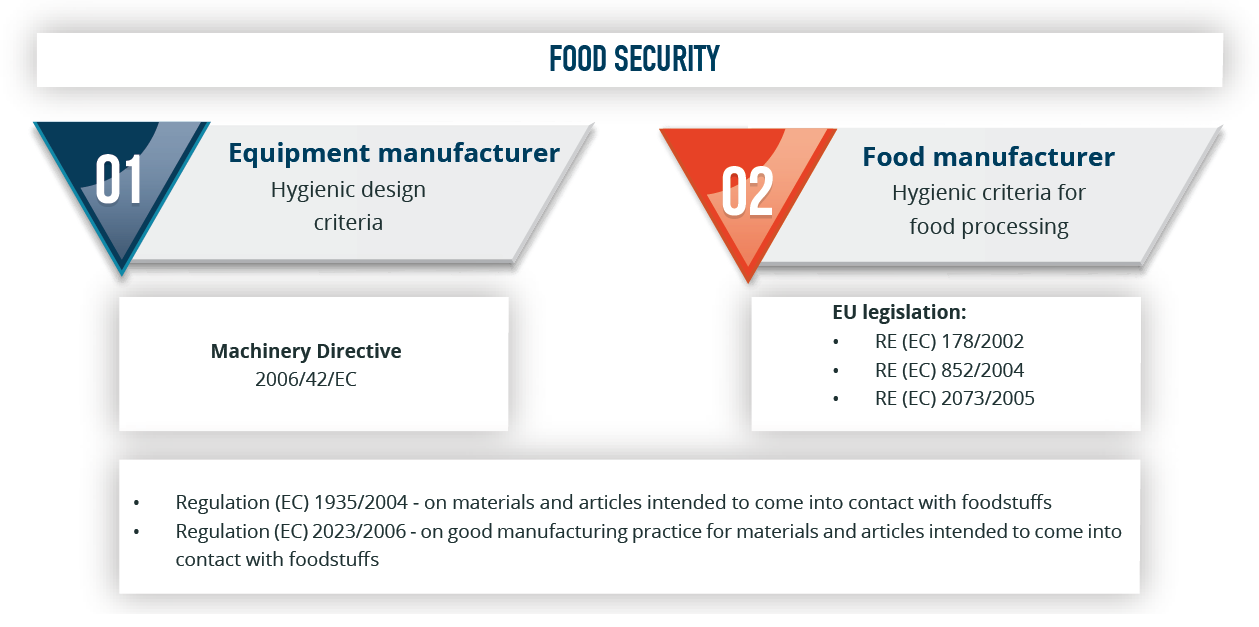

Product safety and security has become a common objective of the food and pharmaceutical sector.

A robust system for reporting, preparing for and responding to potential food safety incidents is in place in the EU. This system is coordinated at EU level by the European Commission in close cooperation with national authorities and with the support of EFSA (European Food Safety Authority).

In Europe, there is also a powerful tool for food safety: RASFF (Rapid Alert System for Food and Feed), which allows the immediate reporting of any food alert that may pose a risk to human or animal health for follow-up and containment measures.

A robust system for reporting, preparing for and responding to potential food safety incidents is in place in the EU. This system is coordinated at EU level by the European Commission in close cooperation with national authorities and with the support of EFSA (European Food Safety Authority).

In Europe, there is also a powerful tool for food safety: RASFF (Rapid Alert System for Food and Feed), which allows the immediate reporting of any food alert that may pose a risk to human or animal health for follow-up and containment measures.