Industry 4.0 in quality control represents a turning point for industrial companies seeking greater efficiency, traceability and competitiveness. Industrial digitalisation not only optimises processes, but also redefines the way in which those responsible for quality, production and operations manage critical data from their lines. In an increasingly regulated global market, adopting smart inspection technologies such as dynamic weight control, artificial vision or X-ray inspection is no longer an option, but a strategic necessity to ensure safety, regulatory compliance and continuous improvement.

INDUSTRY 4.0 IN QUALITY CONTROL: INDUSTRIAL

DIGITISATION FOR OPERATIONAL EXCELLENCE

by marketing on 15 de September de 2025

INDUSTRIAL DIGITISATION AS A PILLAR OF INDUSTRY 4.0

What does digitisation mean for quality control?

Industrial digitisation involves integrating data capture systems, sensors and connected platforms that enable total control of the process.

In the field of quality control, this means:

· Online inspection using dynamic weight control, artificial vision, X-rays or metal detectors.

· Real-time monitoring of critical production variables.

· Automatic feedback systems that correct deviations without manual intervention.

Industrial digitisation involves integrating data capture systems, sensors and connected platforms that enable total control of the process.

In the field of quality control, this means:

· Online inspection using dynamic weight control, artificial vision, X-rays or metal detectors.

· Real-time monitoring of critical production variables.

· Automatic feedback systems that correct deviations without manual intervention.

Relevant regulations and standards

Digitisation is aligned with international regulations such as:

· ISO 9001:2015 (quality management).

· ISO 22000 (food safety).

· BRCGS and IFS for food industries.

· Regulation (EU) 2017/625 for official controls in the food chain.

· Legal metrological control of weighing and packaging equipment in regulated sectors.

Digitisation is aligned with international regulations such as:

· ISO 9001:2015 (quality management).

· ISO 22000 (food safety).

· BRCGS and IFS for food industries.

· Regulation (EU) 2017/625 for official controls in the food chain.

· Legal metrological control of weighing and packaging equipment in regulated sectors.

BENEFITS OF INDUSTRY 4.0 IN QUALITY CONTROL

Implementing industrial digitisation solutions offers tangible competitive advantages:

1. Integral traceability: automatic data recording for audits and certifications.

2. Reduction of human error: thanks to automation in inspection.

3. Increased productivity: fewer stoppages and faster adjustments.

4. Regulatory compliance: alignment with national and international regulations, including metrological standards for weight control.

5. Data-driven decisions: advanced analytics for continuous improvement.

1. Integral traceability: automatic data recording for audits and certifications.

2. Reduction of human error: thanks to automation in inspection.

3. Increased productivity: fewer stoppages and faster adjustments.

4. Regulatory compliance: alignment with national and international regulations, including metrological standards for weight control.

5. Data-driven decisions: advanced analytics for continuous improvement.

CASE STUDIES IN INDUSTRY

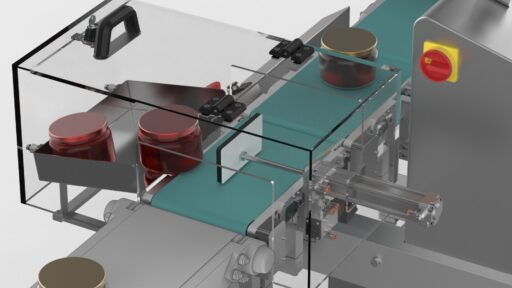

Food and beverages: dynamic checkweighers

In the food industry, where product safety and legal compliance are priorities, dynamic weight control becomes an essential ally. This system ensures that each package complies with the exact quantity established by regulations, avoiding penalties, reducing complaints and optimising the use of raw materials. In addition, it allows integration with feedback systems that automatically adjust the dosing or filling machine, boosting productivity and minimising waste.

Pharmaceutical: X-ray inspection systems

The pharmaceutical sector is governed by the highest standards of quality and traceability. Here, X-ray inspection plays a crucial role in detecting foreign bodies, broken tablets, incomplete blister packs or defective ampoules. This non-invasive technology helps to ensure that each unit complies with the parameters required by international regulatory standards, providing confidence and reducing the risk of product recalls in a market where precision is non-negotiable.

Infant feeding: vision systems

In infant nutrition, where product safety and excellence are paramount, machine vision systems offer comprehensive quality control. These solutions make it possible to verify the integrity of packaging, the correct printing of labels with nutritional information and expiry dates, as well as the presence of critical elements such as safety caps. Thanks to machine vision, every product intended for babies and children is guaranteed to meet the strictest regulatory requirements and consumer confidence standards.

VIT4 BY VARPE: SOFTWARE FOR INDUSTRY 4.0 IN QUALITY CONTROL

¿What is VIT4?

VIT4 is a programme designed to store and manage data generated by Varpe equipment during production. It is based on IoT (Internet of Things) concepts, converted into IIoT (Industrial Internet of Things), which allows machines to be interconnected with analysis platforms, machine-to-machine (M2M) support, telemetry and remote monitoring.

Key features of VIT4 for quality control

· Real-time monitoring of Varpe equipment: Allows you to view the status of equipment, current production, rejected units, deviations and average production weight.

· Consolidated production and customised reports: Stores production data from Varpe equipment and presents it in reports that can be filtered by date, format, rejections, etc. Ideal for audits and trend analysis.

· Maintenance alerts and forecasts: VIT4 sends advance warnings about future events, required maintenance, and deviations that could affect quality control.

· Data export: Allows data to be extracted in .csv format for integration with ERP or external analysis systems.

· User and equipment management: Configuration of users with different access levels, detailed views or grid views of multiple machines.

· Consolidated production and customised reports: Stores production data from Varpe equipment and presents it in reports that can be filtered by date, format, rejections, etc. Ideal for audits and trend analysis.

· Maintenance alerts and forecasts: VIT4 sends advance warnings about future events, required maintenance, and deviations that could affect quality control.

· Data export: Allows data to be extracted in .csv format for integration with ERP or external analysis systems.

· User and equipment management: Configuration of users with different access levels, detailed views or grid views of multiple machines.

How VIT4 strengthens control and digitisation

· Improves traceability by providing accurate automatic records of production, weight, rejects and deviations.

· Brings transparency to the quality control process, with accessible real-time and consolidated data, facilitating rapid corrective decision-making.

· Supports regulatory compliance, especially where historical data, exact weight and metrological conformity are required.

· Integrates dynamic weight control with overall plant supervision: from a single dashboard, you can monitor weighing equipment, X-rays, metal detectors, etc., in line with the philosophy of industrial digitalisation.

· Brings transparency to the quality control process, with accessible real-time and consolidated data, facilitating rapid corrective decision-making.

· Supports regulatory compliance, especially where historical data, exact weight and metrological conformity are required.

· Integrates dynamic weight control with overall plant supervision: from a single dashboard, you can monitor weighing equipment, X-rays, metal detectors, etc., in line with the philosophy of industrial digitalisation.

CONCLUSION

Industry 4.0 in quality control, supported by tools such as Varpe's VIT4, represents a decisive lever for industrial companies to guarantee safe products, efficient processes and regulatory compliance in increasingly demanding environments. Dynamic weight control, together with machine vision, X-rays, metal detection and complete industrial digitisation, not only provides technical advantages, but also enables more sustainable and resilient business models.

Learn more about advanced inspection solutions, VIT4 software and quality control tailored to your industry.

Contact your manager and implement the ultimate quality control in your line · T: +34 937 479 570 · E: sales@varpe.es.

Learn more about advanced inspection solutions, VIT4 software and quality control tailored to your industry.

Contact your manager and implement the ultimate quality control in your line · T: +34 937 479 570 · E: sales@varpe.es.