The V2000 Classic checkweigher helps you control the quality and profitability of your production thanks to advanced weighing electronics, maximum accuracy and state-of-the-art software. The system

checks one hundred percent of the manufactured products and rejects all those that are not within the manufacturing standard, specifically and individually for each established format.

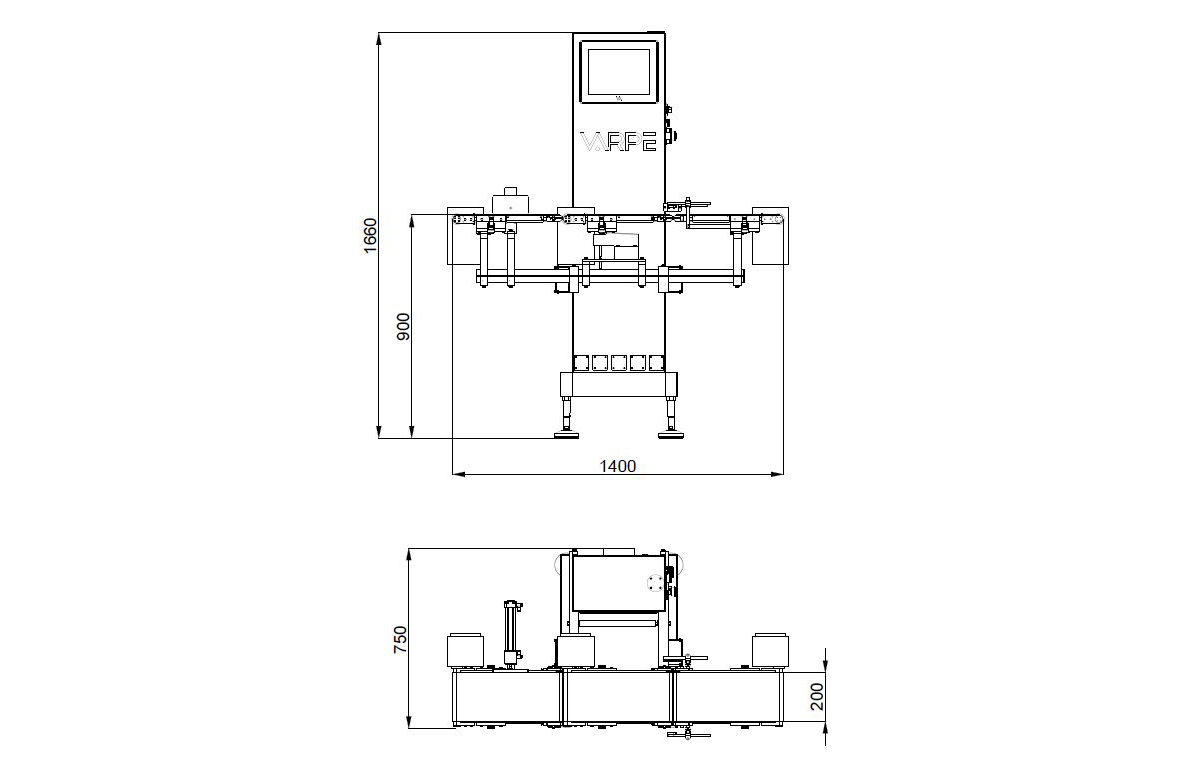

The V2000 Classic is designed according to a modular concept that provides flexibility and versatility, adapting to your needs and the space available on the line. It also facilitates the maintenance and assembly of optional elements such as rejection systems, protections, alarms or other accessories.

The equipment has elements that are easy to disassemble and clean, with the frame made of AISI 304 stainless steel and a 12" touch screen. There is the possibility of adding hygienic features for those industries that require it.

The checkweigher can incorporate specific functionalities such as price-weighing systems, feedback and extensive standard industrial communication systems such as Modbus or OPC/UA. In addition, it can be equipped with VIT4 data control software.

checks one hundred percent of the manufactured products and rejects all those that are not within the manufacturing standard, specifically and individually for each established format.

The V2000 Classic is designed according to a modular concept that provides flexibility and versatility, adapting to your needs and the space available on the line. It also facilitates the maintenance and assembly of optional elements such as rejection systems, protections, alarms or other accessories.

The equipment has elements that are easy to disassemble and clean, with the frame made of AISI 304 stainless steel and a 12" touch screen. There is the possibility of adding hygienic features for those industries that require it.

The checkweigher can incorporate specific functionalities such as price-weighing systems, feedback and extensive standard industrial communication systems such as Modbus or OPC/UA. In addition, it can be equipped with VIT4 data control software.