The V2000 Wafer checkweigher has been specifically designed for the wafer market. This equipment helps to control the quality and profitability of the production thanks to its exhaustive weight control, especially in the regulation of the filling.

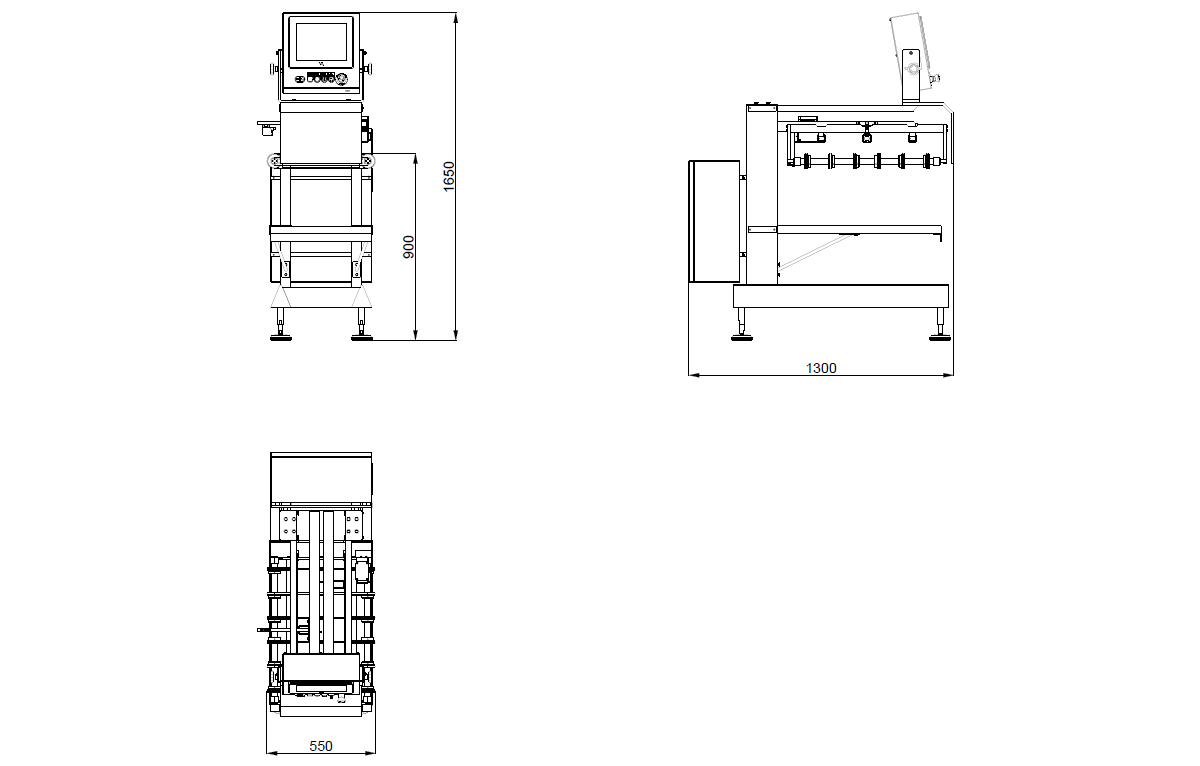

The V2000 Wafer has a robust and stable construction that requires little installation space. Its modular system provides versatility and makes easier the installation and commissioning of the equipment. It also offers the possibility of a hygienic approach in its design to meet the needs of the market in terms of cleaning and accessibility.

The V2000 Wafer system includes advanced weighing electronics, maximum precision, state-of-the-art software, a touch screen and extensive communications systems. All this allows to bring its production closer to Industry 4.0.

The V2000 Wafer has a robust and stable construction that requires little installation space. Its modular system provides versatility and makes easier the installation and commissioning of the equipment. It also offers the possibility of a hygienic approach in its design to meet the needs of the market in terms of cleaning and accessibility.

The V2000 Wafer system includes advanced weighing electronics, maximum precision, state-of-the-art software, a touch screen and extensive communications systems. All this allows to bring its production closer to Industry 4.0.