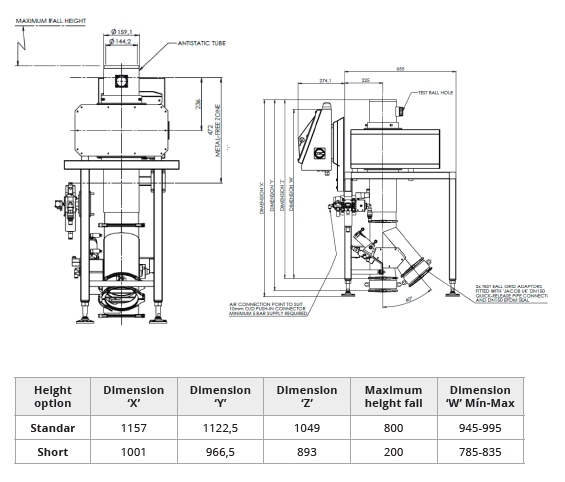

The Varpe MD FREE FALL HD metal detector is designed to inspect bulk food industry products. This model incorporates a touch screen with an attractive user interface designed to simplify set-up, operation and maintenance, minimising user error. The system offers optimised mechanics to deliver performance improvements through variable frequency detection (31 to 882 KHz), which allows for optimised detection levels around a wide range of products with varying conditions, including wet or dry. It is also prepared to work in low pressure washdown environments and is IP66 protected.

It complies with strict international standards such as IFS, BRC and FSMA; and can also be supplied with the highest level of compliance to meet stringent retail codes of practice (COP).

It complies with strict international standards such as IFS, BRC and FSMA; and can also be supplied with the highest level of compliance to meet stringent retail codes of practice (COP).