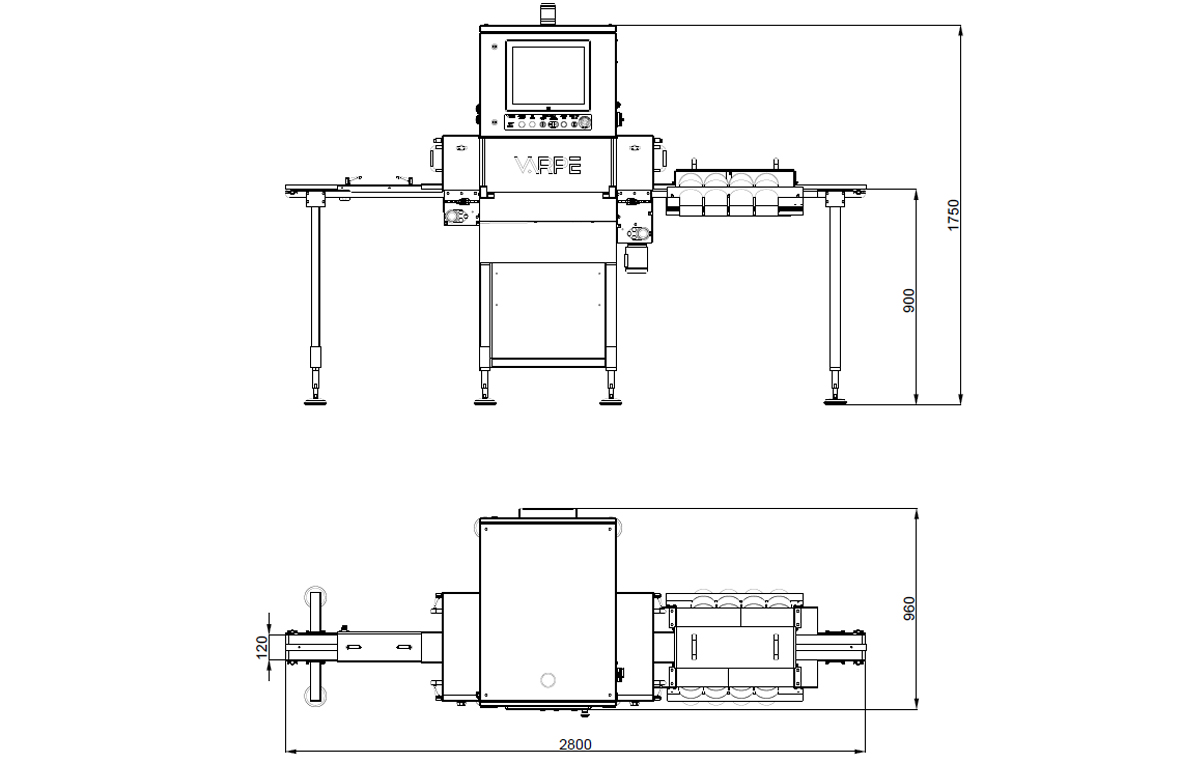

The new generation of X-ray inspection equipment of Varpe offers innovative global solutions for the inspection of products with vertical beam, guaranteeing the integrity of your production.

The advanced X-ray technology of the IRIX DV CORK allows a precise classification of the product based on its natural morphology. It also checks for damaged corks, breaks and inspects the inner layers of the product. In addition, it allows a double processing of the product.

It is possible to have several simultaneous inspection tracks with different levels of classification depending on the defect that has been detected and its natural quality.

This system complies with the international safety standards governing ionizing radiation emissions.

It is listed under the certification of exempt equipment granted by the General Direction of Policies and Mines, with the approval of the Council Of Nuclear Safety Number NHMX224, published in the BOE No. 90 on April 15, 2017.

The advanced X-ray technology of the IRIX DV CORK allows a precise classification of the product based on its natural morphology. It also checks for damaged corks, breaks and inspects the inner layers of the product. In addition, it allows a double processing of the product.

It is possible to have several simultaneous inspection tracks with different levels of classification depending on the defect that has been detected and its natural quality.

This system complies with the international safety standards governing ionizing radiation emissions.

It is listed under the certification of exempt equipment granted by the General Direction of Policies and Mines, with the approval of the Council Of Nuclear Safety Number NHMX224, published in the BOE No. 90 on April 15, 2017.