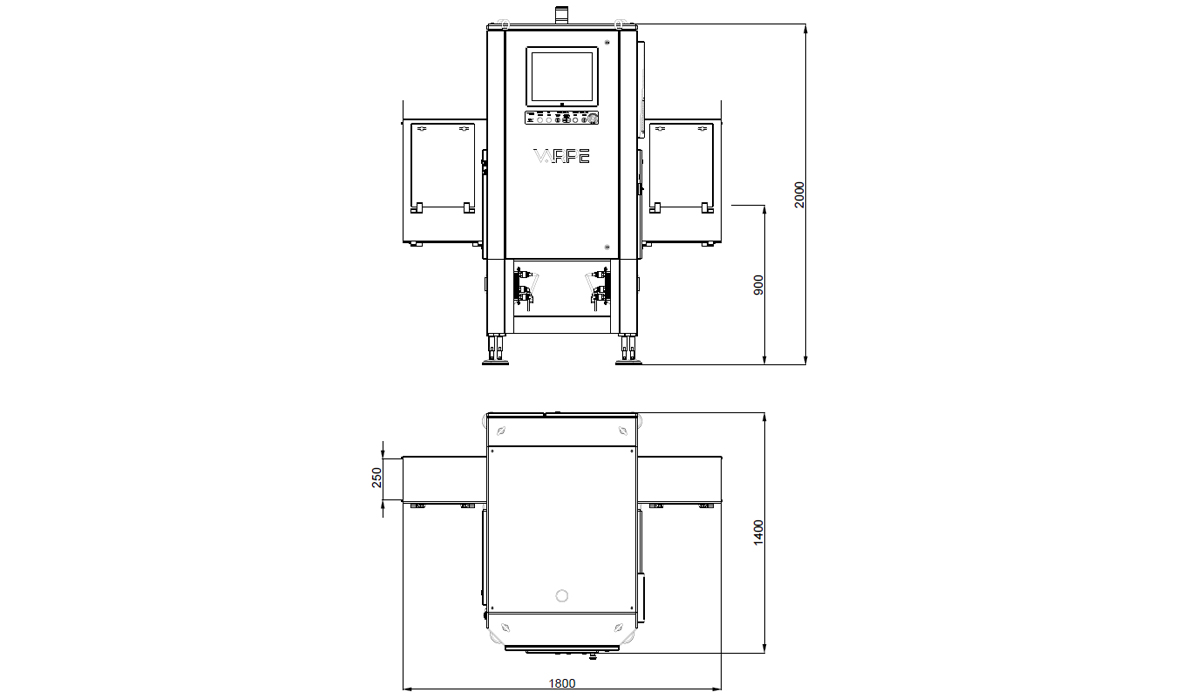

The new generation of side-shot X-ray inspection equipment of Varpe offers innovative global solutions for product inspection, ensuring the safety and integrity of your production. The included side beam can be bottom-up for inspection of cans, jars or bottles where the interior is dense, or top-down for low dense products where it is easy that the contaminant ends up lodged in the base.

The advanced X-ray technology of IRIX DL Side achieves exceptional levels of detection of ferric and non-ferrous material, stainless steel, glass, calcified bones, thorns and stones. It also simultaneously verifies product damage, breakage, mass measurement with estimated weight, and item count within the product. Its compact structure allows a direct coupling with the production line.

This system complies with the international safety standards governing ionizing radiation emissions.

It is listed under the certification of exempt equipment granted by the General Direction of Policies and Mines, with the approval of the Council Of Nuclear Safety Number NHMX224, published in the BOE No. 90 on April 15, 2017.

The advanced X-ray technology of IRIX DL Side achieves exceptional levels of detection of ferric and non-ferrous material, stainless steel, glass, calcified bones, thorns and stones. It also simultaneously verifies product damage, breakage, mass measurement with estimated weight, and item count within the product. Its compact structure allows a direct coupling with the production line.

This system complies with the international safety standards governing ionizing radiation emissions.

It is listed under the certification of exempt equipment granted by the General Direction of Policies and Mines, with the approval of the Council Of Nuclear Safety Number NHMX224, published in the BOE No. 90 on April 15, 2017.