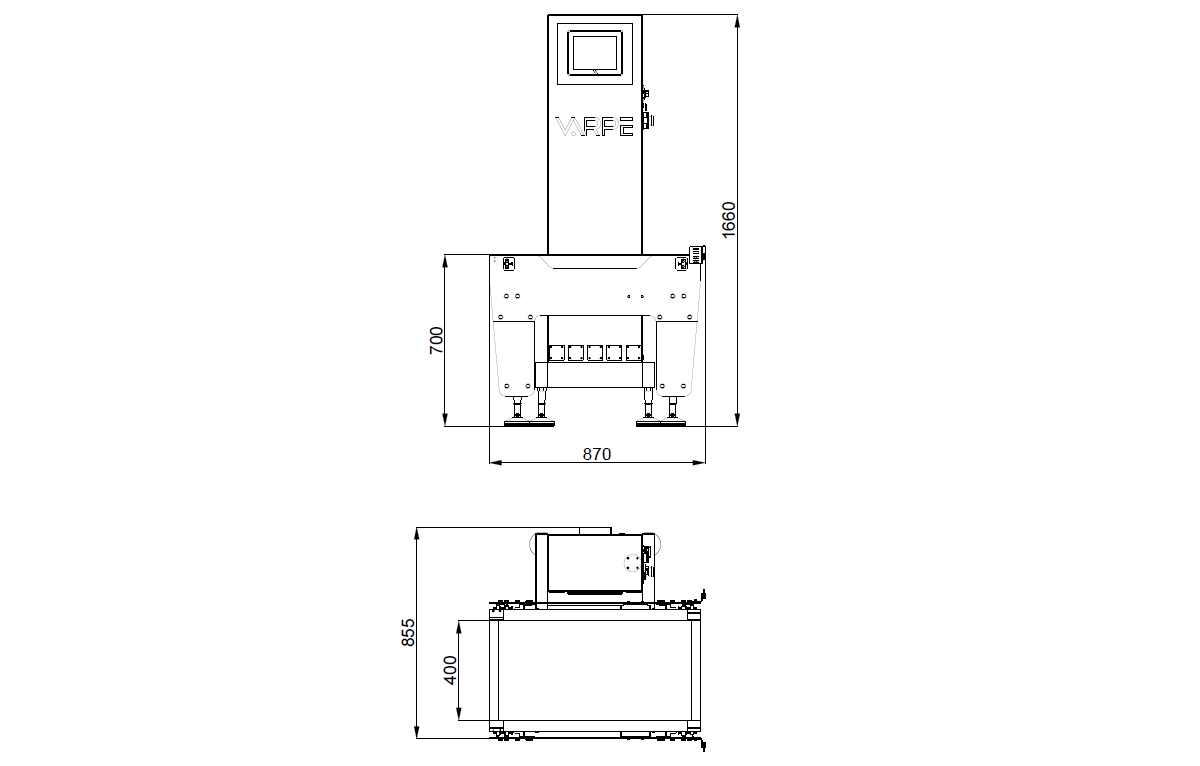

The V2000 Robust checkweigher is ideal for bulky and / or heavy products, which require an extremely strong, precise equipment with a conveyor that responds to their specific needs to help to control production quality.

The V2000 Robust offers a robust and stable construction that requires little installation space. It includes advanced weighing electronics, excellent accuracy, state-of-the-art software, extensive communication systems, and the option of a hygienic approach in its design to meet the needs of the market in terms of cleanliness and accessibility.

Its modular system provides flexibility and facilitates the installation and commissioning of the equipment.

The V2000 Robust offers a robust and stable construction that requires little installation space. It includes advanced weighing electronics, excellent accuracy, state-of-the-art software, extensive communication systems, and the option of a hygienic approach in its design to meet the needs of the market in terms of cleanliness and accessibility.

Its modular system provides flexibility and facilitates the installation and commissioning of the equipment.