The Essentia V2000 checkweigher has the essential functionalities to help control the quality of production thanks to the automatic weighing of 100% of the products without stopping the production line. The equipment is able to indicate and/or reject all products that are not part of the manufacturing standard individually for each established format.

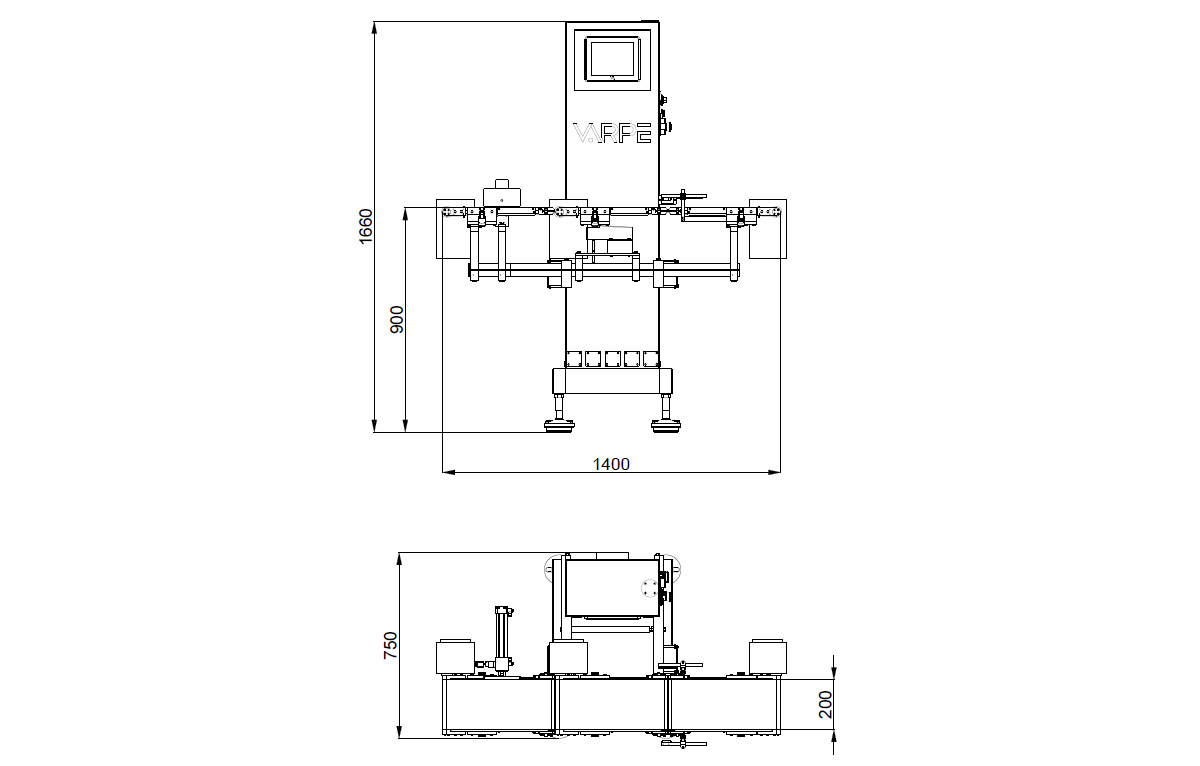

The V2000 Essentia requires little installation space and has a modular system that provides versatility and facilitates its assembly and start-up.

It includes software with basic functionalities oriented to support quality control, as well as a touch screen and several communication systems.

The V2000 Essentia requires little installation space and has a modular system that provides versatility and facilitates its assembly and start-up.

It includes software with basic functionalities oriented to support quality control, as well as a touch screen and several communication systems.