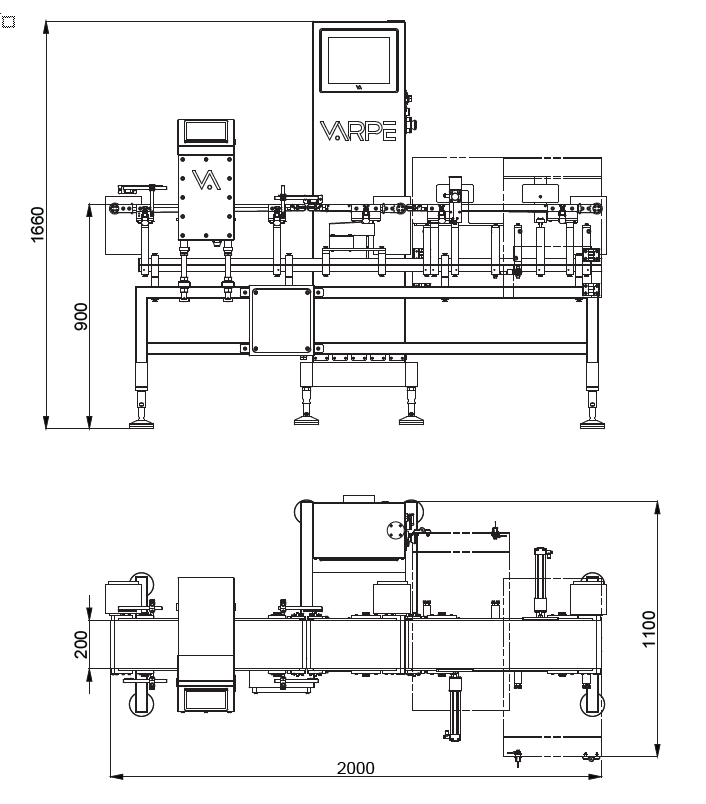

Varpe combined equipment integrate the latest technology in dynamic weighing and metal detection on a single system in order to perform rigorous testing of weighing and metal detection.

The ideal solution for checkweighing and detection of metal particles in products packaged in the production line.

The ideal solution for checkweighing and detection of metal particles in products packaged in the production line.