Varpe’s MD PIPELINE HD metal detector is designed to inspect pumped and flowing products such as meat pastes, soups, sauces, jams or dairy products.

The IQ4 Pipeline is a robust system designed for both sterilisation in place (SIP) and fast cleaning depending on the application. In addition, this equipment complies with EN1672-2 hygiene standards.

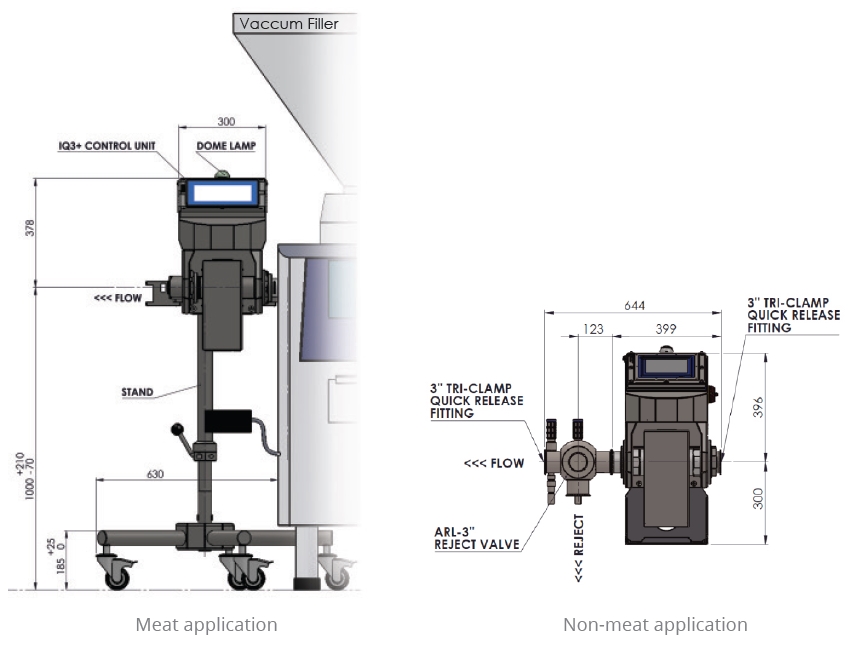

Designed to be on a mobile stand with gas strut for height adjustment (meat applications) or a fixed L-stand (non-meat applications), the MD PIPELINE HD is built to IP69K rating, making it suitable for harsh environments.

This model incorporates a touch screen with a simple and attractive user interface.

The system offers optimised mechanics to deliver performance improvements through variable frequency detection (31 to 937 KHz), which allows for optimised detection levels around a wide range of products with different conditions, even if wet or dry.

The IQ4 Pipeline is a robust system designed for both sterilisation in place (SIP) and fast cleaning depending on the application. In addition, this equipment complies with EN1672-2 hygiene standards.

Designed to be on a mobile stand with gas strut for height adjustment (meat applications) or a fixed L-stand (non-meat applications), the MD PIPELINE HD is built to IP69K rating, making it suitable for harsh environments.

This model incorporates a touch screen with a simple and attractive user interface.

The system offers optimised mechanics to deliver performance improvements through variable frequency detection (31 to 937 KHz), which allows for optimised detection levels around a wide range of products with different conditions, even if wet or dry.