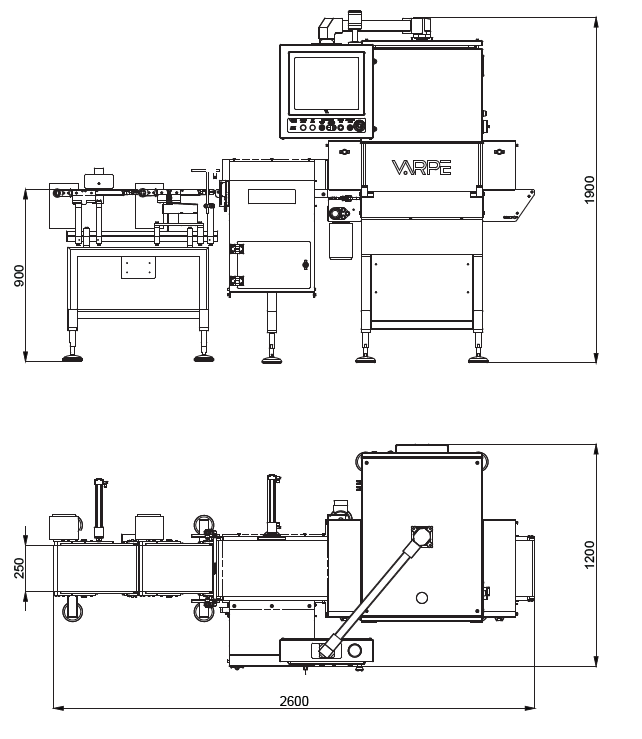

Latest technology in detection of contaminants with X-Ray and checkweighing with centralized management for both functionalities.

Built in with advanced electronic weighing, high accuracy and newest generation software. Robust and stable.

Unbeatable protection of foreign bodies and contam¬inants such as glass, metal, stone, bone and plastic, ensuring the security and integrity on your production.

COMBO RX X-Ray inspection system is listed under the certification of exempt equipment granted by the General Direction of Policies and Mines, with the approval of the Council Of Nuclear Safety number NHMX224, published in the BOE No. 90 on April 15th, 2017.

Built in with advanced electronic weighing, high accuracy and newest generation software. Robust and stable.

Unbeatable protection of foreign bodies and contam¬inants such as glass, metal, stone, bone and plastic, ensuring the security and integrity on your production.

COMBO RX X-Ray inspection system is listed under the certification of exempt equipment granted by the General Direction of Policies and Mines, with the approval of the Council Of Nuclear Safety number NHMX224, published in the BOE No. 90 on April 15th, 2017.