Metal detectors are a commonly used detection method for metal contaminants within factories. The metal detector will check if the product is contaminated with metallic elements as it is transported through the production line, diverting it if a contaminant is found.

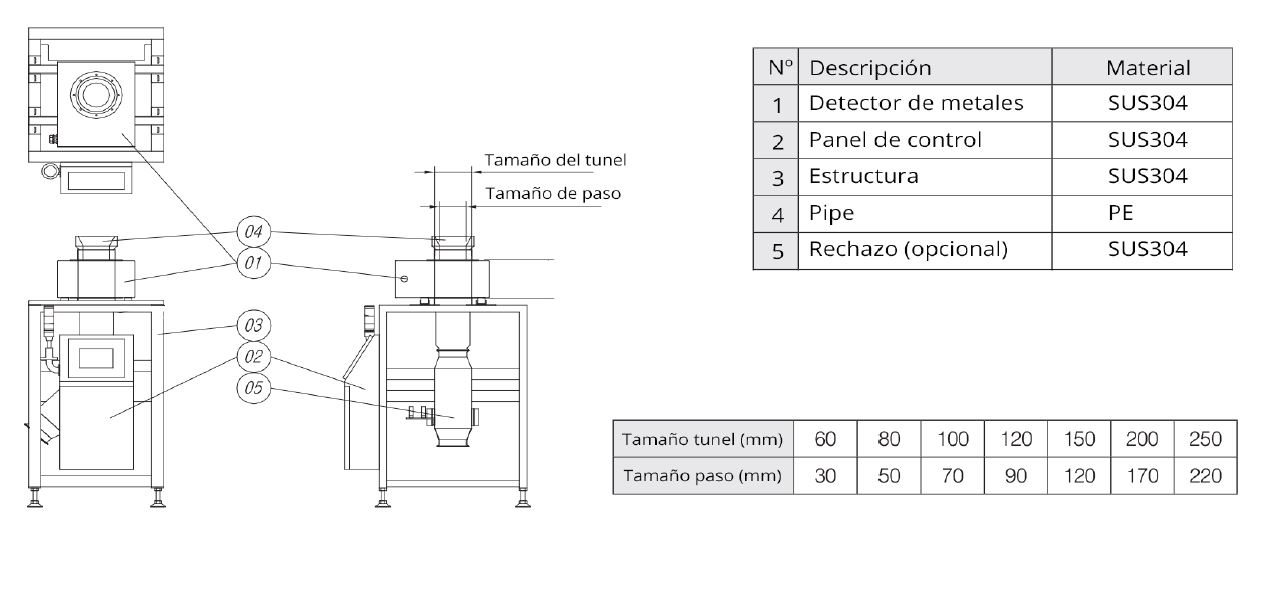

The MD FREE FALL ESSENTIA metal detector is specifically designed to inspect materials in the form of fine grains or bulk materials. It has a uniquely designed frame and spiral geometry that allows automatic product identification and maximum sensitivity for detection of metal contaminants without the need for adjustment.

High-frequency signals can be selected depending on the properties of the product to be inspected, so the metal detector offers optimum performance in detecting different products. It offers numerous features such as self-diagnostics, detection history storage, optional printer, Ethernet port connection, USB disk connection, various rejection systems and more.

The MD FREE FALL ESSENTIA metal detector is specifically designed to inspect materials in the form of fine grains or bulk materials. It has a uniquely designed frame and spiral geometry that allows automatic product identification and maximum sensitivity for detection of metal contaminants without the need for adjustment.

High-frequency signals can be selected depending on the properties of the product to be inspected, so the metal detector offers optimum performance in detecting different products. It offers numerous features such as self-diagnostics, detection history storage, optional printer, Ethernet port connection, USB disk connection, various rejection systems and more.