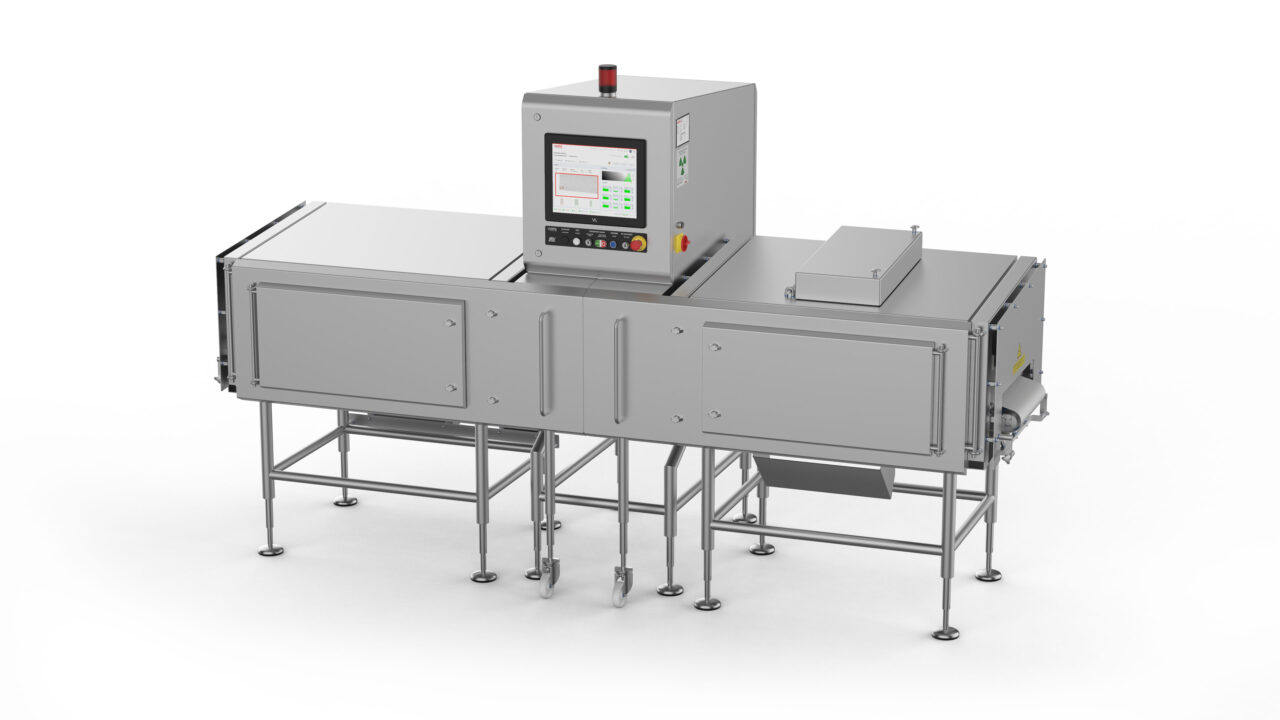

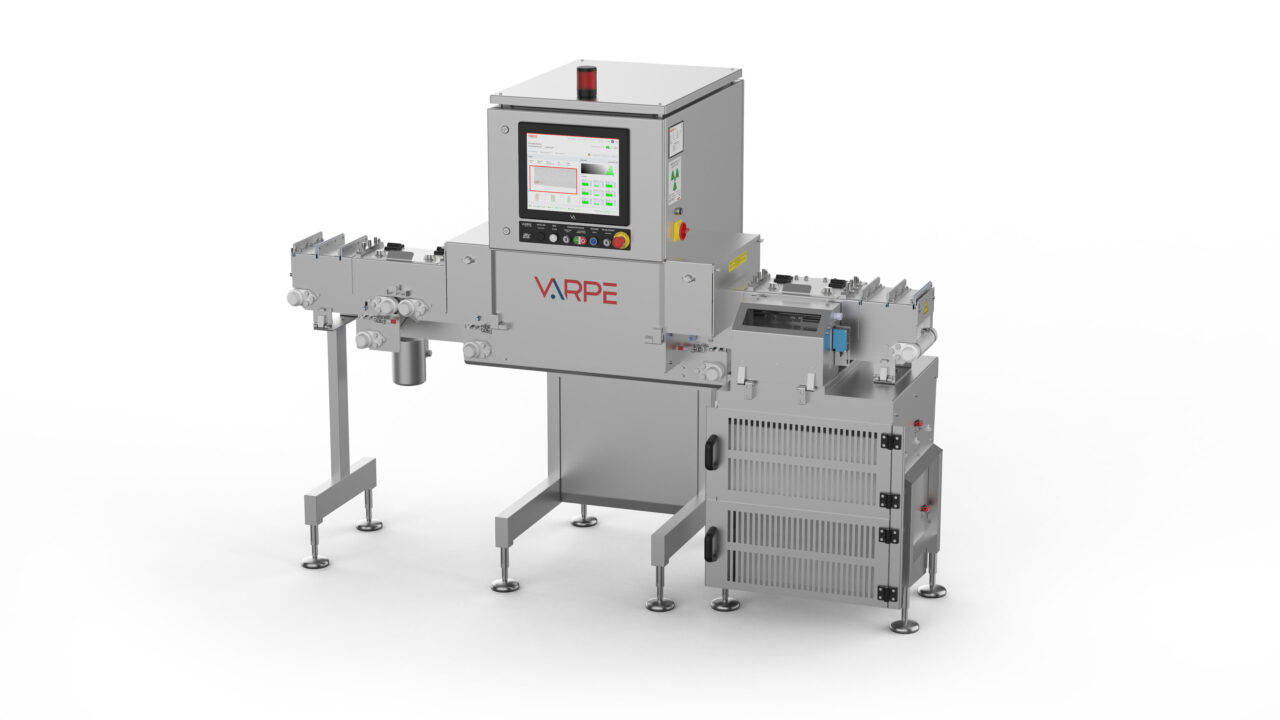

X-ray inspection equipment can be installed in different production stages: in the beginning with the bulk product, during the processing or at the end with the final packaging. In any of these phases, the system searches contaminants such as metal, glass, mineral stones, calcified bone, and plastic.

Thanks to the technology used in the X-Ray inspection equipment of Varpe, most of the needs for a reliable detection of contaminants with a determined morphologic and density features in the food and beverage industry are fulfilled.

Thanks to the technology used in the X-Ray inspection equipment of Varpe, most of the needs for a reliable detection of contaminants with a determined morphologic and density features in the food and beverage industry are fulfilled.