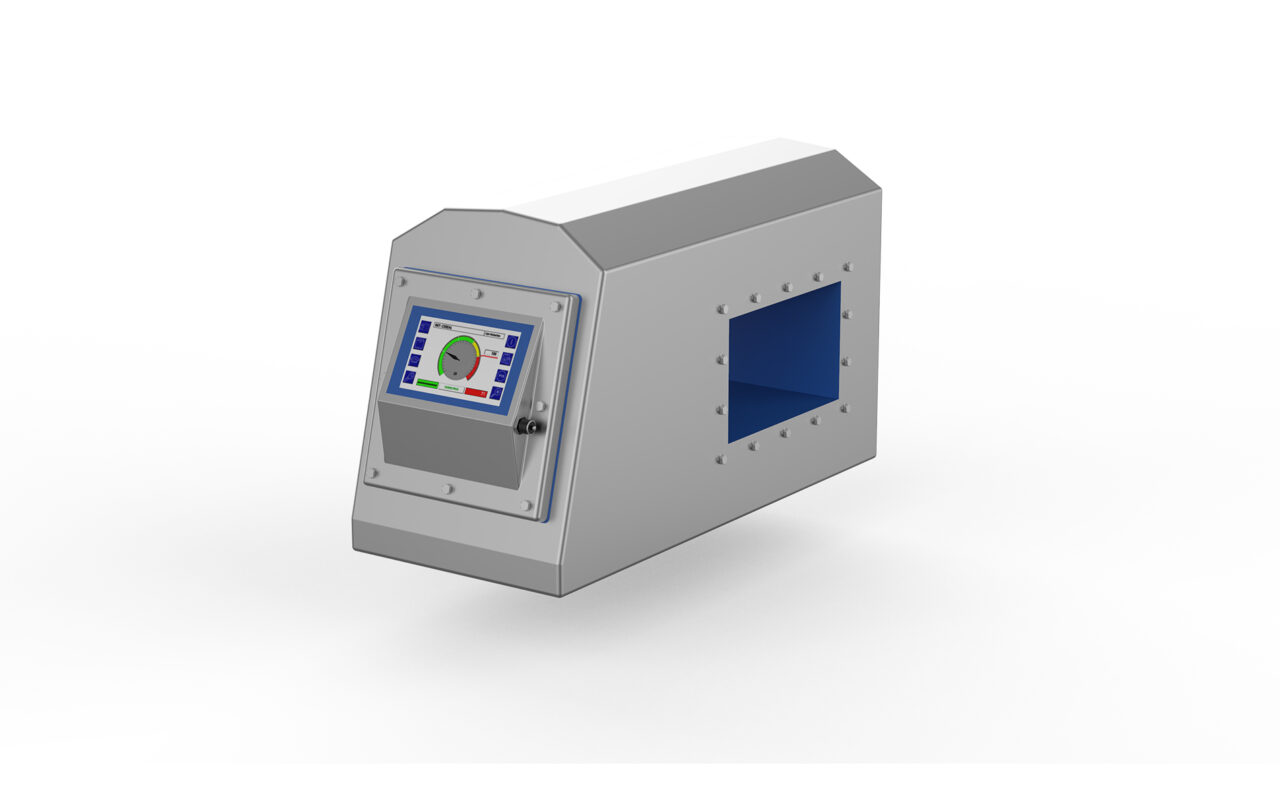

The metal detector system checks if any product is contaminated with metal while it runs through the production line, separating it from the rest when required.

It also includes the revolutionary technology of variable frequency that optimizes the detection levels in a wide range of different product conditions.

It also includes the revolutionary technology of variable frequency that optimizes the detection levels in a wide range of different product conditions.