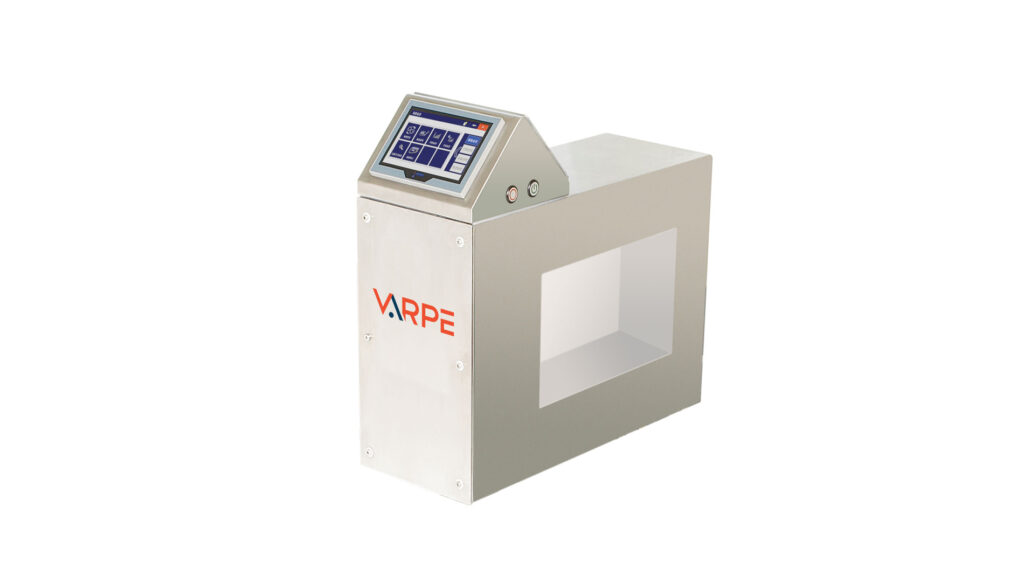

VARPE global solutions comply with all regulations and security requirements within food and beverage industry, improving the processes of its production lines and product quality. In addition to this, Varpe takes into account the hygienic design during the conceptualization, manufacturing and installation of its equipment, guaranteeing food safety.

Varpe has a considerable presence in national and international food and beverage markets, and has a wide experience in weight control and X-ray inspection equipment for ready-made food, frozen foods, pastries, pre-prepared food, canned food, beverages and other convenience food.

Varpe has a considerable presence in national and international food and beverage markets, and has a wide experience in weight control and X-ray inspection equipment for ready-made food, frozen foods, pastries, pre-prepared food, canned food, beverages and other convenience food.